-

2026-01-26 2026-01-26

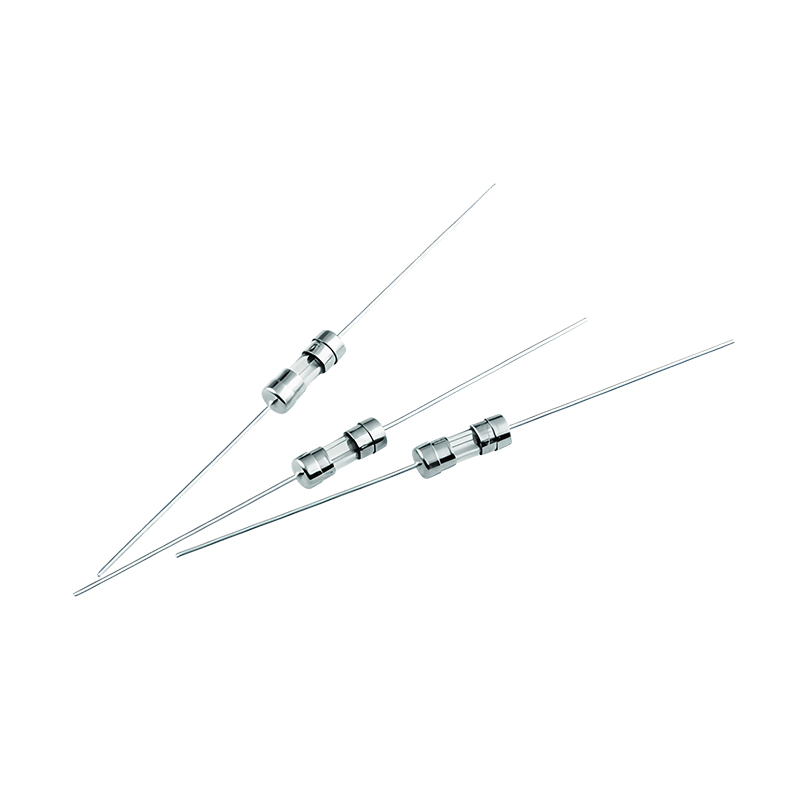

What are the key advantages of using high-quality electrolytic copper strip in enhancing product durability in copper belt safety caps?

Copper belt safety caps, precision-stamped from high-quality electrolytic copper strip, significantly improve product durability and safety thanks to their superior material properties and advanced manufacturing processes, making them an ideal choice for -

2026-01-12 2026-01-12

How to avoid defects such as cracks affecting quality during the processing of high-precision copper strip?

During the processing of high-precision copper strips, defects such as cracks can significantly affect their quality, especially in terms of thickness uniformity, surface finish, and mechanical properties. -

2025-12-29 2025-12-29

What causes the contact resistance of a copper tape connector to increase after long-term use?

Mechanical vibration or temperature cycling can cause micron-level relative sliding at the contact interface of the copper tape connector, i.e., fretting wear. -

2025-12-15 2025-12-15

What defects are prone to occur during high-precision brass strip welding and what are the preventive measures?

Welding areas should be well-ventilated to promptly remove zinc oxide fumes generated by zinc evaporation and protect the health of welders. -

2025-12-01 2025-12-01

Does the contact resistance of a copper tape connector change significantly after repeated plugging and unplugging?

As a key component in electrical connections, the change in contact resistance of copper tape connectors after repeated insertions and removals directly affects connection stability and system reliability. -

2025-11-17 2025-11-17

What impact does the heat treatment process of high precision brass strips have on its grain size?

Excessive temperature may cause abnormal grain coarsening, reducing material properties.