Does the contact resistance of a copper tape connector change significantly after repeated plugging and unplugging?

Release Time : 2025-12-01

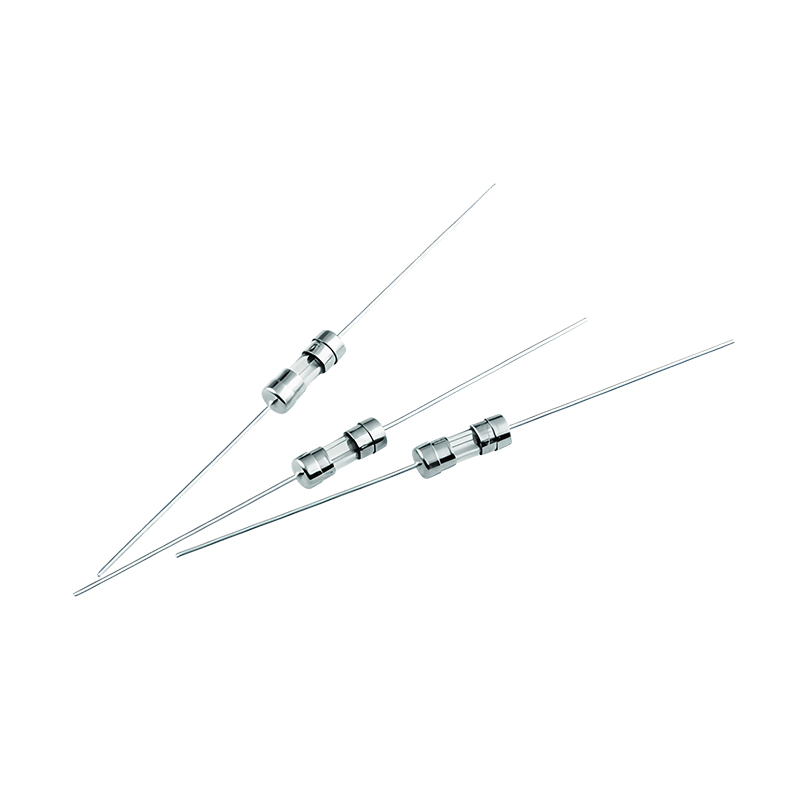

As a critical component in electrical connections, the contact resistance of a copper tape connector after repeated mating and removal directly affects connection stability and system reliability. Contact resistance comprises conductor resistance, film layer resistance, and localized resistance, with the film layer resistance significantly influenced by surface oxidation, contamination, and wear. During mating and removal, the contact surface of the copper tape connector undergoes dynamic friction and stress, leading to changes in its surface microstructure and consequently affecting the evolution of contact resistance.

In the initial mating and removal phase, the film layer on the contact surface is partially damaged by mechanical friction, exposing a fresh metal surface. At this point, the film layer resistance temporarily decreases, and the overall contact resistance may show a slight downward trend. During this stage, the integrity of the plating material (such as gold or tin plating) plays a crucial role in resistance stability; a high-quality plating can delay direct wear of the base metal. However, with increasing mating and removal cycles, microscopic wear marks gradually appear on the contact surface, increasing surface roughness. The actual contact area decreases due to mechanical damage, resulting in a significant increase in localized resistance.

The material properties of the copper tape connector have a decisive influence on resistance changes. While pure copper conductors offer excellent conductivity, their low hardness makes them more susceptible to plastic deformation and surface scratches during frequent insertion and removal, accelerating the deterioration of contact resistance. In contrast, copper alloys (such as copper-tin alloys and copper-nickel alloys) enhance hardness and wear resistance through alloying, effectively suppressing surface damage caused by insertion and removal, thereby slowing down the rate of resistance increase. Furthermore, differences in plating processes also affect resistance changes; for example, electroless nickel plating exhibits more stable contact resistance over long-term insertion and removal due to its superior uniformity and adhesion compared to electroplating.

The synergistic effect of environmental factors and insertion/removal parameters further complicates the evolution of contact resistance. High-temperature environments accelerate the growth of oxide films on copper surfaces, especially under humid conditions, where the oxide layer and contaminants form a composite insulating film, leading to a sharp increase in film resistance. Insertion and removal operations under vibration or impact loads exacerbate fretting wear on the contact surface, generating metal debris and oxide particles. These debris accumulate in the contact area, forming an insulating layer and causing a stepwise increase in contact resistance. Meanwhile, the insertion and extraction force directly affects the contact pressure distribution. Excessive force can lead to localized plastic deformation of the contact surface, causing permanent damage; insufficient force, on the other hand, can exacerbate fretting wear and oxidation due to low contact pressure.

Design optimization is a crucial means of suppressing contact resistance degradation. By increasing the contact area, employing elastic contact structures, or optimizing the contact surface geometry, stress concentration during insertion and extraction can be dispersed, reducing localized wear. For example, a hyperboloid contact design can improve the self-cleaning ability of the contact surface and reduce the risk of debris accumulation; while a spring probe structure maintains a stable electrical connection by continuously compensating for contact pressure. Furthermore, surface treatment technologies (such as laser texturing and ion implantation) can enhance the wear resistance and corrosion resistance of the contact surface, further extending the connector's lifespan.

In practical applications, the contact resistance variation of copper tape connectors needs to be comprehensively evaluated in conjunction with specific operating conditions. Under low-frequency insertion and extraction, clean environments, and mild temperature conditions, the contact resistance of high-quality connectors can remain stable over a long period; however, in high-frequency insertion and extraction, severe vibration, or harsh environments, the risk of resistance increase increases significantly. Therefore, selecting appropriate connector specifications (such as mating life rating and protection rating) for different application scenarios, and coordinating with regular maintenance (such as cleaning contact surfaces and checking tightness), are key measures to ensure the long-term reliable operation of the system.