-

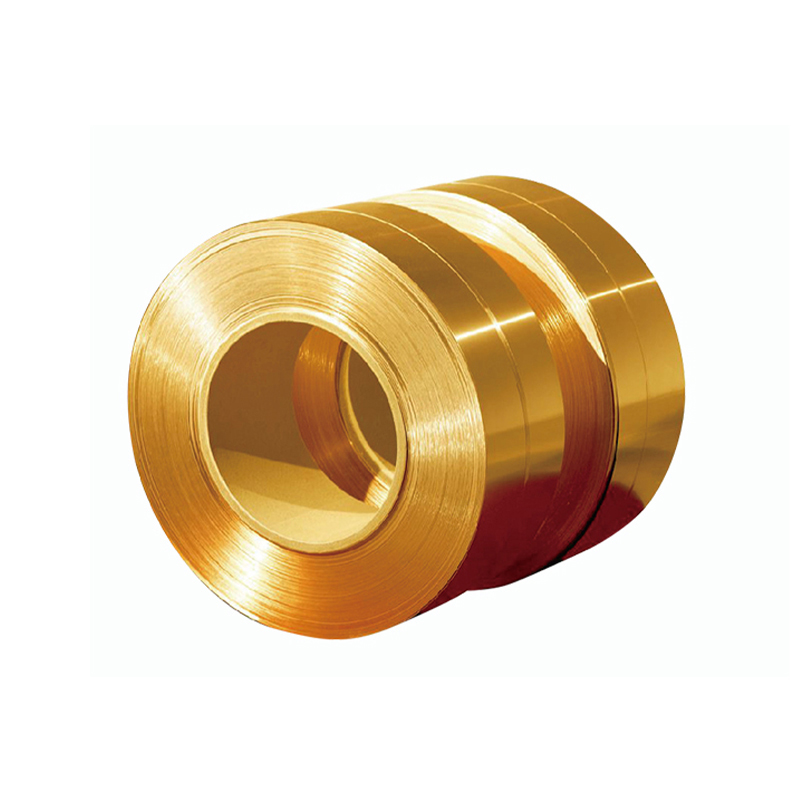

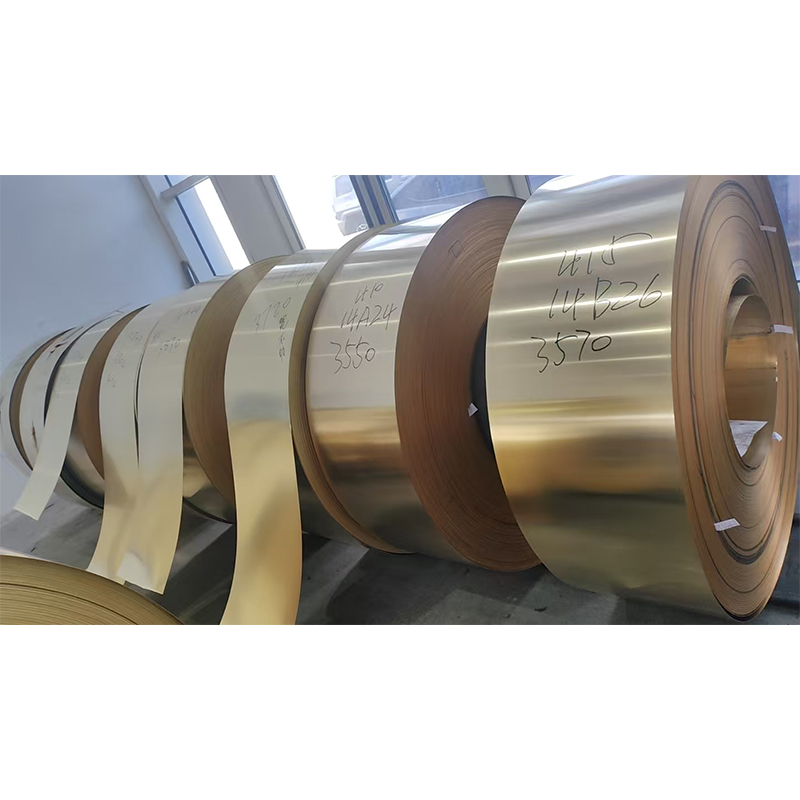

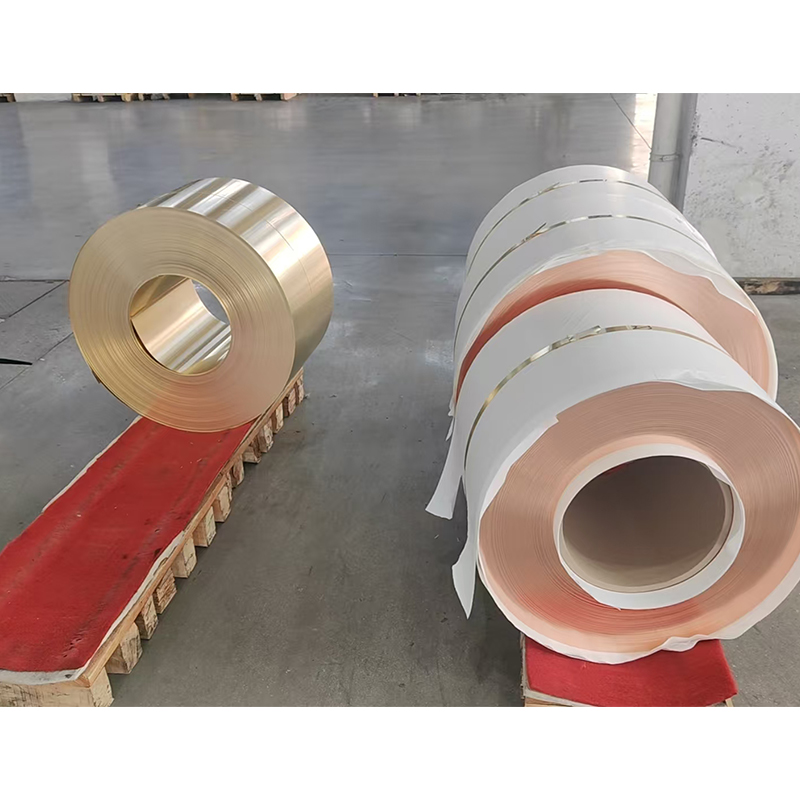

Width 200/400, thickness can be customized according to customer requirements. Specifications can be customized according to customer needs, brass thickness 0.15-2.0. It can be divided into small rolls according to customer roll weight requirements, regular width 400 or 200 can be used, or both sides can be added up to 400 wide. Roll weight can be 300-3200 kg according to customer requirements.

Yuanding Copper's high-precision brass strips mainly include H62 (C2800), H65 (C2680), H68 (C2620), H70 (C2600) and other grades.

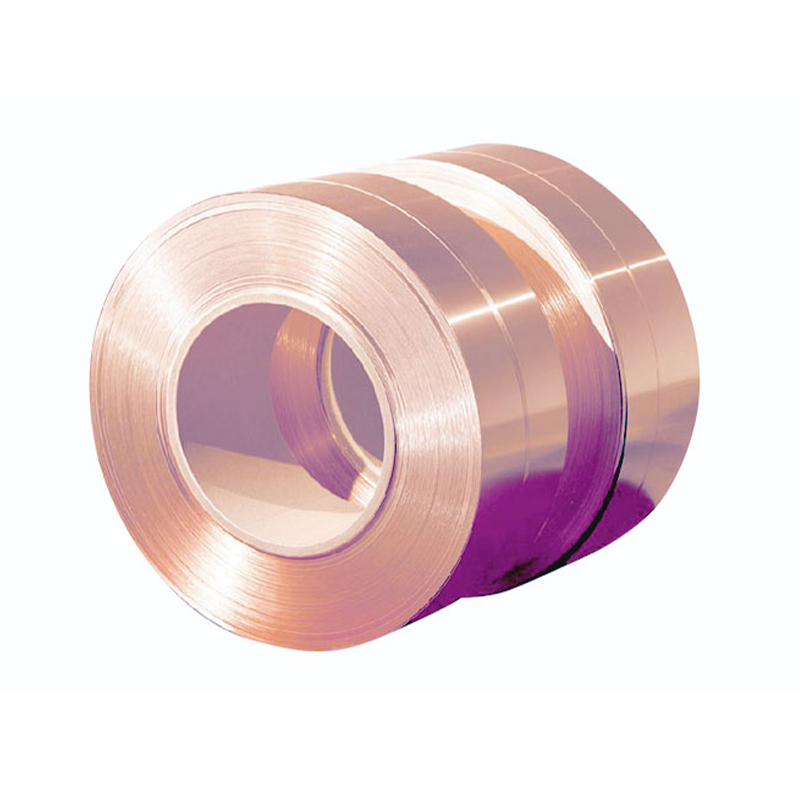

H90 copper alloy has good electrical conductivity, thermal conductivity, corrosion resistance, plasticity, processability and surface treatment properties. It can be plated with metal and coated with enamel. It is mainly suitable for water supply and drainage pipes, medals, artworks, water tank belts and bimetallic strips.

H85 copper alloy has high strength and good plasticity. It can withstand cold and hot pressure processing well. It also has good welding and corrosion resistance and is easy to form. It is used for rivets, washers, nuts, conduits, barometers, screens, radiator parts, etc.

H70 has good color, processability, ductility, suitable for drawing, and easy electroplating or painting. It can be used for deep drawing, such as bullet shells and shells. Horn locks, electronic parts, automobile water tanks, copper pipes.

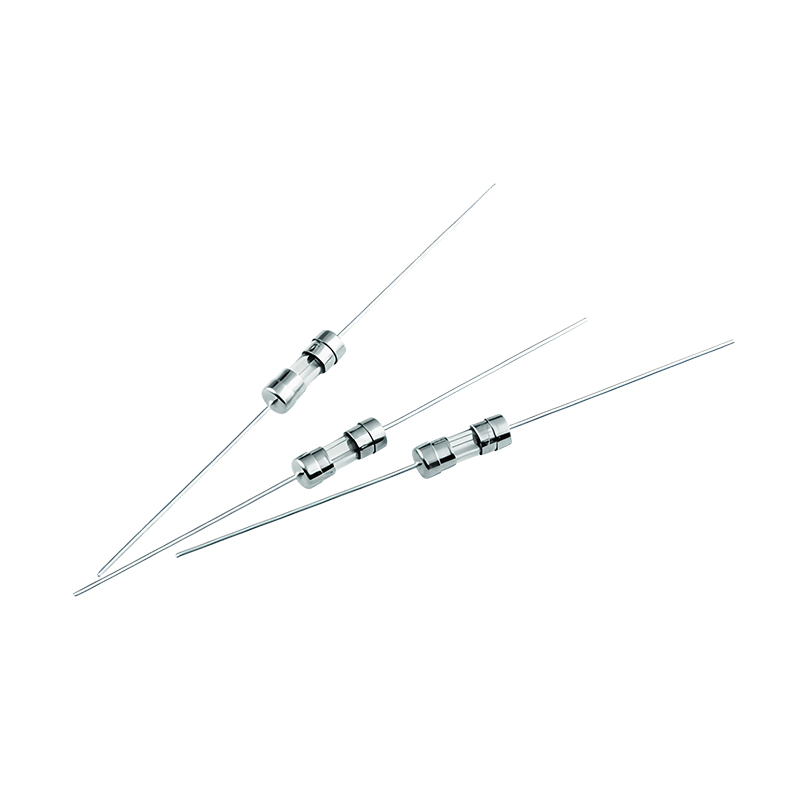

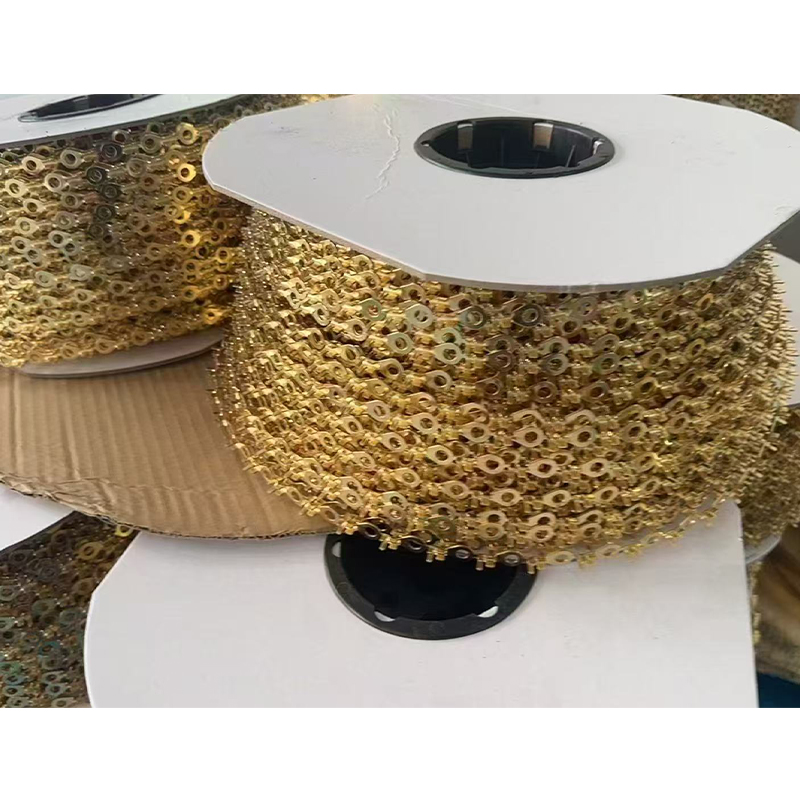

H65 brass strip has beautiful color, good mechanical properties, process properties, corrosion resistance, wear resistance and electrical conductivity, and is widely used in electronic appliances, hardware devices and other industries. Yuanding Company's H65 brass strip is widely used in fuse copper caps, battery electrode copper caps, automotive terminal connectors, buttons, decorative parts and other industries due to its excellent process properties.

-

Mechanical properties

Brand

state

Tensile test

Hardness test

standard

Thickness mm

Tensile strength Rm MPa

Elongation after break A11.3%

Vickers hardness HV

H90

O60

≥0.2

≥245

≥35

/

GB/T2059-2017

H02

330-440

≥5

/

H04

≥390

≥3

/

H85

O60

≥0.2

≥260

≥40

≤85

H02

305-380

≥15

80-115

H04

≥350

/

≥105

H70 H68 H65

O60

≥0.2

≥290

≥40

≤90

H01

325-410

≥35

85-115

H02

355-460

≥25

100-130

H04

410-540

≥13

120-160

H06

520-620

≥4

150-190

H08

≥570

/

≥180

H62

O60

≥0.2

≥290

≥35

≤95

H02

350-470

≥20

90-130

H04

410-630

≥10

125-165

H06

≥585

≥2.5

≥155