How to avoid defects such as cracks affecting quality during the processing of high-precision copper strip?

Release Time : 2026-01-12

In the processing of high-precision copper strips, defects such as cracks significantly affect their quality, particularly in terms of thickness uniformity, surface finish, and mechanical properties. To avoid these problems, a comprehensive approach involving material selection, process control, equipment optimization, and environmental management is necessary to establish a complete quality assurance system.

Material selection is fundamental to preventing cracks. High-precision copper strips require extremely high raw material purity. Impurities such as lead and bismuth significantly reduce material plasticity, leading to grain boundary weakening during processing and causing intergranular cracking. Therefore, high-purity electrolytic copper or special-grade copper materials must be selected, and strict smelting process control is required to reduce inclusions and gas content. For example, using vacuum melting or inert gas protected melting can effectively reduce the solubility of gases such as hydrogen and oxygen, preventing the formation of subcutaneous pores and thus reducing cracks caused by pore rupture during rolling.

Process control is the core element in preventing cracks. During the hot rolling stage, strict control of heating temperature and holding time is crucial to avoid grain coarsening or overheating due to excessively high temperatures, or insufficient plasticity due to excessively low temperatures. For example, before hot rolling, the ingot needs to undergo homogenization annealing to eliminate casting stress and compositional segregation, improving the material's hot working properties. In the cold rolling stage, the reduction per pass must be rationally allocated to avoid excessive local deformation caused by excessive reduction in a single pass. For high-precision copper strips, multi-pass rolling with small reductions is typically used, combined with intermediate annealing to eliminate work hardening and restore material plasticity. The annealing process requires precise control of temperature and time to prevent grain coarsening due to overheating or stress concentration due to undercooling.

Equipment optimization is a vital guarantee against cracking. The precision of the rolling mill roll system directly affects the uniformity of copper strip thickness and strip shape quality. Excessive roll surface roughness can lead to scratches on the copper strip surface, while uneven roll gaps can cause localized stress concentrations, resulting in cracks. Therefore, regular grinding and polishing of the rolls is necessary to ensure roll surface smoothness and roll gap parallelism. Meanwhile, the use of high-rigidity rolling mills and hydraulic bending roll devices effectively compensates for thickness fluctuations caused by roll deformation during rolling, avoiding additional stress due to poor strip shape. Furthermore, stable control of rolling speed and tension is crucial; speed fluctuations or sudden tension changes can cause copper strip vibration, leading to surface scratches or edge cracks.

Lubrication and cooling are key auxiliary measures to prevent cracking. During rolling, lubricant reduces friction between the rolls and the copper strip, lowers deformation resistance, and removes frictional heat, preventing localized overheating and material performance degradation. For high-precision copper strip, high-viscosity, high-extreme-pressure rolling oil is typically used, combined with a spray system for uniform lubrication. The cooling system must ensure uniform temperature between the rolls and the copper strip to avoid thermal stress concentration due to excessive temperature differences. For example, combining internal roll circulation cooling with external spray cooling can effectively control rolling temperature and reduce crack formation.

Environmental management is an often overlooked aspect of preventing cracking. High-precision copper strip processing has extremely high requirements for environmental humidity and cleanliness. Excessive humidity can cause copper strip surface oxidation, forming an oxide scale that flakes off and scratches the surface during rolling. Therefore, processing must be carried out in a temperature- and humidity-controlled workshop equipped with an air purification system to reduce contamination of the copper strip surface by dust and other impurities. Furthermore, strict regulations must be followed regarding operator attire and tool cleaning to prevent the introduction of contaminants due to human error.

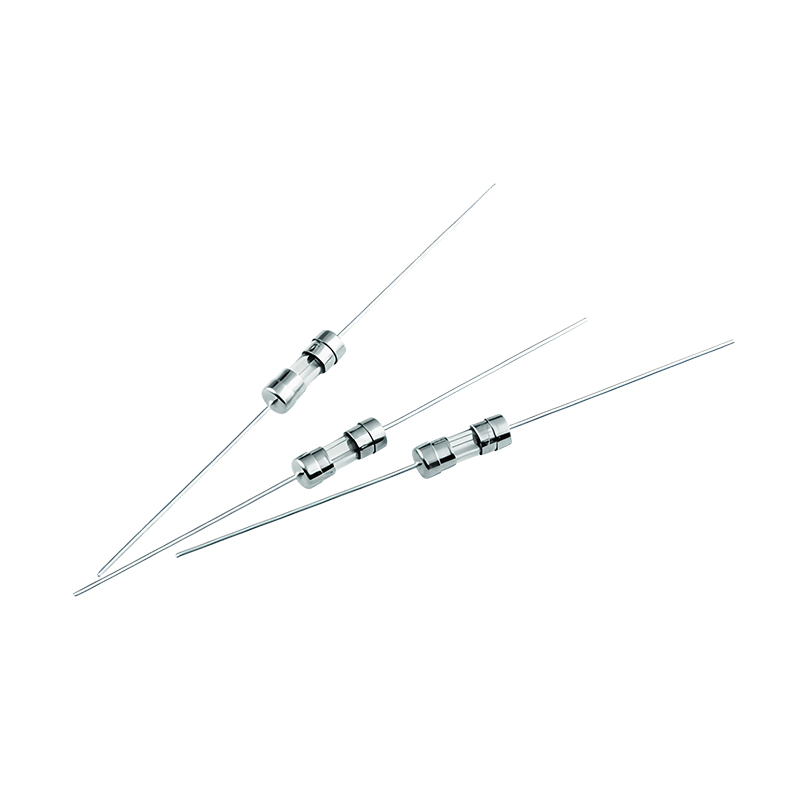

Online detection and feedback control are the final line of defense against cracks. Online detection equipment such as laser thickness gauges and shape gauges can monitor the copper strip thickness, shape, and surface quality in real time, feeding the data back to the control system. When an anomaly is detected, the system can automatically adjust rolling parameters, such as reduction, tension, or speed, to eliminate the risk of cracking. For example, using a closed-loop thickness control system can dynamically adjust the roll gap based on the measured thickness, ensuring stable thickness accuracy. Simultaneously, combined with machine vision technology, defects on the copper strip surface can be identified and classified, and the locations of cracks and other defects can be marked in a timely manner for subsequent processing.

Preventing cracks in high-precision copper strip processing requires a comprehensive approach encompassing material selection, process control, equipment optimization, lubrication and cooling, environmental management, and online detection. Systematic quality control measures can significantly improve the processing quality of copper strips and meet the stringent requirements for material performance in high-end fields.