What causes the contact resistance of a copper tape connector to increase after long-term use?

Release Time : 2025-12-29

The increased contact resistance of copper tape connectors after prolonged use is primarily due to the combined effects of material properties, environmental factors, and mechanical stress. Specifically, this manifests as oxidation corrosion, fretting wear, contact pressure attenuation, and contamination deposition.

During long-term use, the contact surface of the copper tape connector undergoes oxidation due to contact with oxygen, water vapor, and harmful industrial gases. Copper oxides (such as copper oxide and basic copper carbonate) form an insulating film on the contact surface, reducing the actual conductive area. Especially in humid or salt spray environments, electrochemical corrosion accelerates film growth, significantly increasing contact resistance. For example, without transition treatment, aluminum in copper-aluminum connectors will preferentially corrode due to the potential difference, forming a loose alumina layer, further deteriorating contact performance.

Mechanical vibration or temperature cycling causes micron-level relative sliding at the contact interface of the copper tape connector, i.e., fretting wear. Repeated friction damages the original contact surface, causing metal debris and oxide particles to accumulate in the contact area. These wear products not only directly hinder current conduction but also fuse at high temperatures to form a more stable insulating layer. For example, in high-frequency vibration environments, microcracks may form on the contact surface due to fatigue wear, accelerating the formation and thickening of the oxide film.

If bolts are not tightened during connector installation, or if creep occurs after long-term operation leading to a decrease in contact pressure, the actual number of contact points will decrease. According to electrical contact theory, contact resistance is inversely proportional to contact pressure; pressure attenuation directly increases resistance. For example, when aluminum busbars are pressurized beyond the critical pressure, insufficient material strength may cause localized bulging, reducing the effective contact area. Furthermore, the difference in thermal expansion coefficients between steel bolts and copper/aluminum conductors can induce creep with temperature changes, further relaxing the contact pressure.

Atmospheric dust, oil, and metal processing residues (such as sand particles and glass shards) can deposit on the contact surface through mechanical adhesion or adsorption. These contaminants not only occupy conductive space but may also embed themselves in microscopic pits in the metal, forming a loose layer of impurities. For example, improper sanding of the contact surface can significantly increase contact resistance due to embedded glass shards. Simultaneously, contaminants may absorb moisture from the environment, forming an electrolyte and exacerbating electrochemical corrosion.

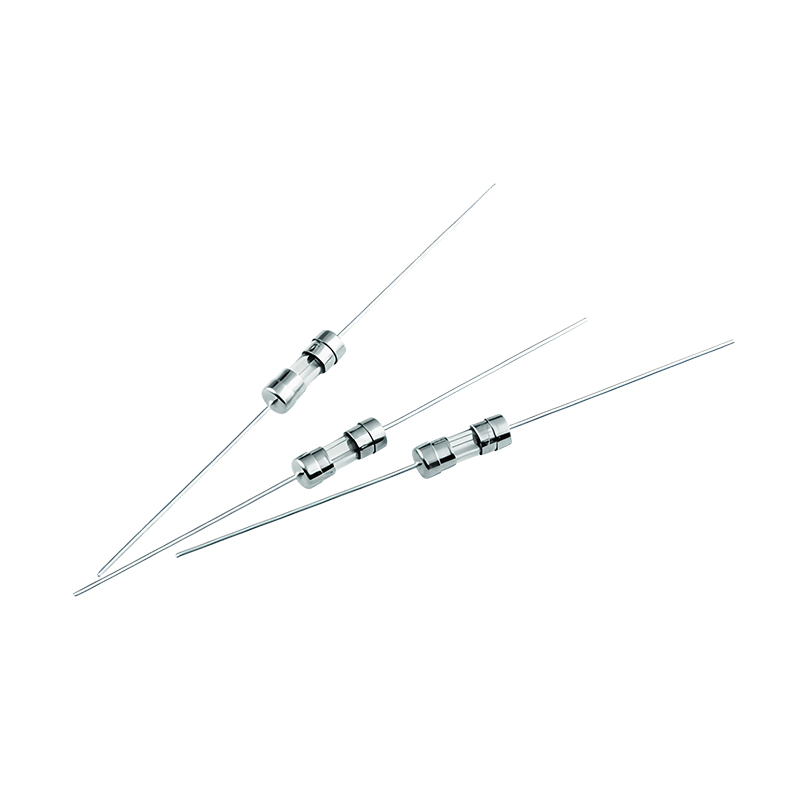

Increased contact resistance can trigger localized temperature rises, creating a vicious cycle. High temperatures accelerate oxidation reactions, promote physical adsorption, and cause insulator decomposition, generating more harmful gases that further corrode the contact surface. For example, when contact resistance exceeds a reasonable range, electrical connectors may experience overheating, leading to insulation aging and even electrical contact failure. Furthermore, high temperatures soften metal materials, causing metal transfer under sliding conditions and exacerbating wear.

To suppress increased contact resistance, a comprehensive approach is needed, addressing material selection, structural design, and maintenance management. Using silver plating, tin plating, or composite plating can improve oxidation resistance; optimizing contact surface geometry increases the actual contact area; using elastic elements to compensate for pressure decay caused by creep; regularly cleaning the contact surface and applying conductive grease; and employing sealing structures or anti-oxidation coatings in harsh environments. These measures effectively delay oxide film formation, reduce fretting wear, and maintain stable contact pressure, thereby ensuring the long-term reliability of the copper tape connector.