What are the key advantages of using high-quality electrolytic copper strip in enhancing product durability in copper belt safety caps?

Release Time : 2026-01-26

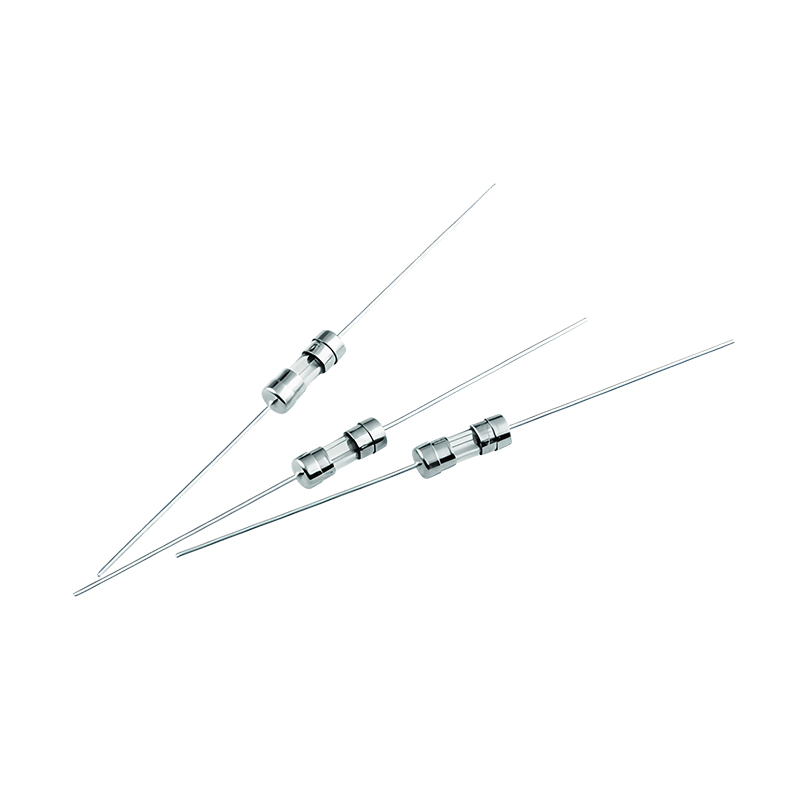

In modern power systems, fuses, as critical overcurrent protection components, bear the important responsibility of quickly interrupting fault currents and preventing equipment damage and fires when circuits are abnormal. The fuse cover, as one of its core structural components, not only affects overall sealing and insulation performance but also plays an irreplaceable role in thermal management, conductivity, and mechanical stability. Copper belt safety caps, precision-stamped from high-quality electrolytic copper strip, significantly improve product durability and safety thanks to their superior material properties and advanced manufacturing processes, making them an ideal choice for high-end power protection equipment.

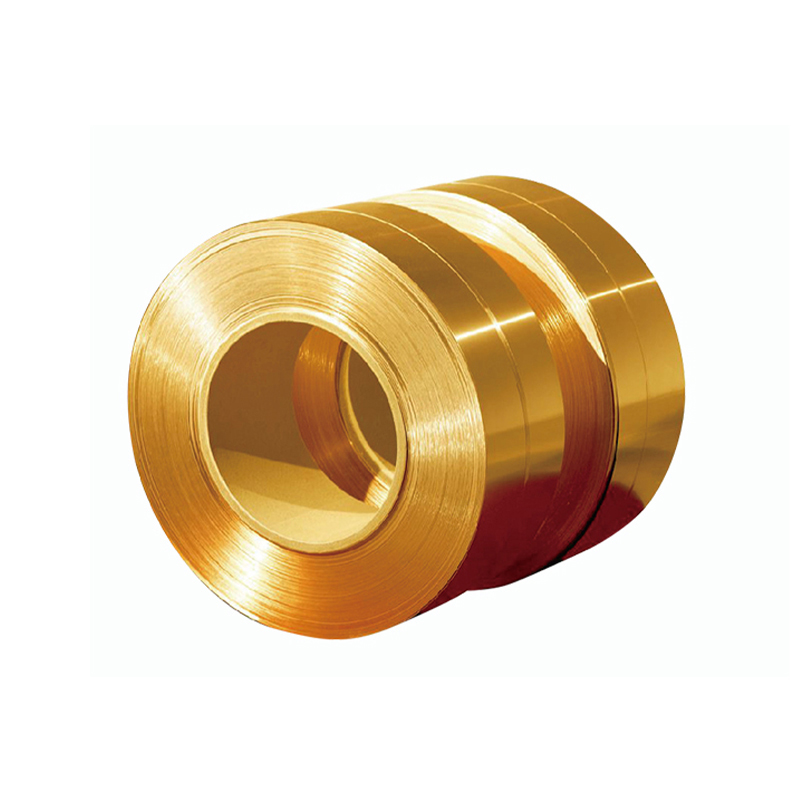

1. High-purity electrolytic copper strip: Rapid thermal conductivity, ensuring thermal stability

High-quality electrolytic copper strip uses high-purity copper as raw material and is manufactured through an electrolytic purification process, achieving a copper content of over 99.95%, possessing excellent electrical and thermal conductivity. During fuse operation, a large amount of Joule heat is generated internally when there is an overload or short circuit. The copper belt safety cap rapidly conducts heat from the molten metal area to the outer casing surface, achieving efficient heat dissipation and preventing excessive localized temperature rise that could lead to insulation aging or casing deformation. This superior thermal conductivity effectively extends the overall lifespan of the fuse, exhibiting stronger thermal stability, especially under frequent start-stop or high-load conditions, significantly improving product durability.

2. Precision Stamping: Seamless Design for Enhanced Reliability

The copper belt safety cap is made from a single piece of electrolytic copper strip, stamped in one piece using high-precision molds, achieving a seamless, integrated structure. Compared to traditional welding or riveting processes, this manufacturing method completely eliminates quality risks such as weld cracking, incomplete welding, and porosity, resulting in a more compact, uniform, and robust cap structure. The overall structure possesses higher mechanical strength and vibration resistance, effectively resisting mechanical impacts during transportation, installation, and operation. Simultaneously, the seamless design enhances sealing, preventing moisture, dust, or corrosive gases from entering the interior, avoiding short circuits or insulation failures caused by internal contamination, and structurally ensuring long-term operational reliability.

3. Suitable Melting Point, Safe and Spatter-Free Fusion

High-quality electrolytic copper strip not only conducts heat quickly, but its melting point is also highly matched to the operating characteristics of the fuse. In extreme fault conditions, when the internal molten element melts, the copper cap maintains its structural integrity at high temperatures, preventing premature melting or explosion, ensuring the arc is effectively confined within the arc-extinguishing chamber. More importantly, copper's physical properties are stable at high temperatures, resulting in a smooth melting process without metal spatter or arcing, greatly reducing the risk of secondary faults or fires. Its inherent excellent flame retardancy and heat insulation further enhance the product's safety level, providing solid protection for power systems.

4. Surface Treatment Process: Corrosion Resistance, Extended Service Life

To prevent copper from oxidizing in humid or corrosive environments, which would increase contact resistance and exacerbate heat generation, the copper belt safety cap is typically silver-plated or nickel-plated on critical contact surfaces. The silver plating layer has excellent conductivity, maintaining low contact resistance, suitable for high-current applications; the nickel plating layer has stronger corrosion resistance and wear resistance, suitable for harsh environments. Both surface treatment processes effectively isolate the copper substrate from the external environment, preventing oxidation and sulfidation, ensuring the stability of electrical connections during long-term use, and significantly extending product maintenance cycles and overall lifespan.

5. Widely Applicable and Withstands Harsh Environments

Copper belt safety caps can be widely used in various circuit breakers, high-voltage/low-voltage fuses, power distribution protection devices, and other electrical equipment. Their material and structural design allows them to withstand high and low temperature cycling shocks ranging from -40℃ to +125℃ and even wider, without deformation or cracking due to thermal expansion and contraction. They maintain stable performance even in harsh environments such as coastal high-salt spray and industrial high-pollution environments, demonstrating excellent environmental adaptability and durability.

Using high-quality electrolytic copper strip as the base material, the copper belt safety cap integrates precision manufacturing and surface treatment technologies, not only improving the product's thermal conductivity, structural strength, and safety, but also fundamentally solving the pain points of traditional covers being prone to aging, corrosion, and failure. It is not only the "shell" of the fuse, but also the "first line of defense" ensuring the safe operation of the circuit. In power systems that pursue high reliability, long lifespan, and high safety standards, this design undoubtedly represents a model of durability and technological progress, injecting solid strength into the stable operation of modern power infrastructure.

1. High-purity electrolytic copper strip: Rapid thermal conductivity, ensuring thermal stability

High-quality electrolytic copper strip uses high-purity copper as raw material and is manufactured through an electrolytic purification process, achieving a copper content of over 99.95%, possessing excellent electrical and thermal conductivity. During fuse operation, a large amount of Joule heat is generated internally when there is an overload or short circuit. The copper belt safety cap rapidly conducts heat from the molten metal area to the outer casing surface, achieving efficient heat dissipation and preventing excessive localized temperature rise that could lead to insulation aging or casing deformation. This superior thermal conductivity effectively extends the overall lifespan of the fuse, exhibiting stronger thermal stability, especially under frequent start-stop or high-load conditions, significantly improving product durability.

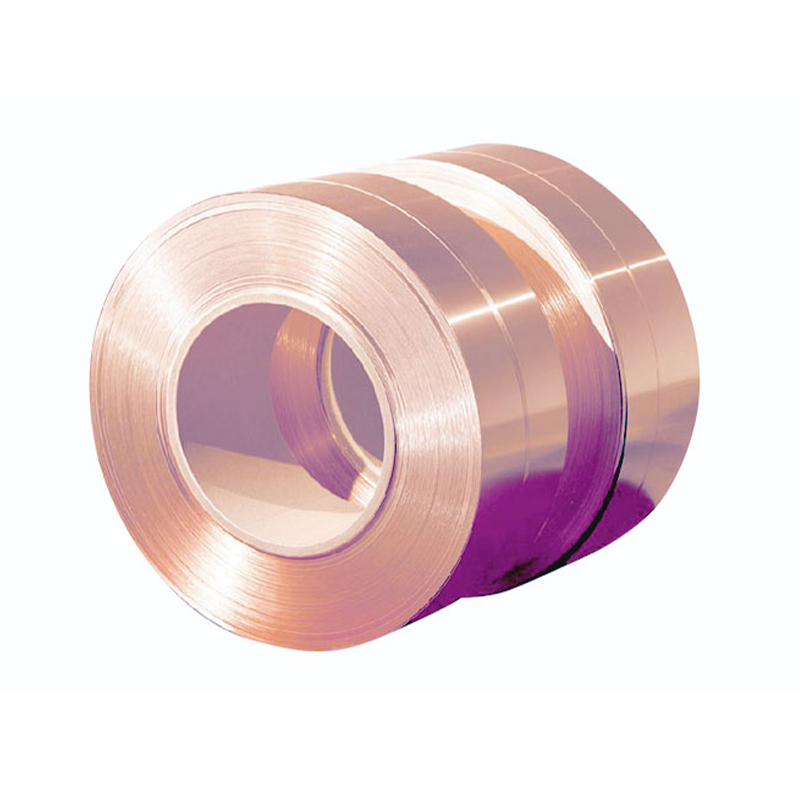

2. Precision Stamping: Seamless Design for Enhanced Reliability

The copper belt safety cap is made from a single piece of electrolytic copper strip, stamped in one piece using high-precision molds, achieving a seamless, integrated structure. Compared to traditional welding or riveting processes, this manufacturing method completely eliminates quality risks such as weld cracking, incomplete welding, and porosity, resulting in a more compact, uniform, and robust cap structure. The overall structure possesses higher mechanical strength and vibration resistance, effectively resisting mechanical impacts during transportation, installation, and operation. Simultaneously, the seamless design enhances sealing, preventing moisture, dust, or corrosive gases from entering the interior, avoiding short circuits or insulation failures caused by internal contamination, and structurally ensuring long-term operational reliability.

3. Suitable Melting Point, Safe and Spatter-Free Fusion

High-quality electrolytic copper strip not only conducts heat quickly, but its melting point is also highly matched to the operating characteristics of the fuse. In extreme fault conditions, when the internal molten element melts, the copper cap maintains its structural integrity at high temperatures, preventing premature melting or explosion, ensuring the arc is effectively confined within the arc-extinguishing chamber. More importantly, copper's physical properties are stable at high temperatures, resulting in a smooth melting process without metal spatter or arcing, greatly reducing the risk of secondary faults or fires. Its inherent excellent flame retardancy and heat insulation further enhance the product's safety level, providing solid protection for power systems.

4. Surface Treatment Process: Corrosion Resistance, Extended Service Life

To prevent copper from oxidizing in humid or corrosive environments, which would increase contact resistance and exacerbate heat generation, the copper belt safety cap is typically silver-plated or nickel-plated on critical contact surfaces. The silver plating layer has excellent conductivity, maintaining low contact resistance, suitable for high-current applications; the nickel plating layer has stronger corrosion resistance and wear resistance, suitable for harsh environments. Both surface treatment processes effectively isolate the copper substrate from the external environment, preventing oxidation and sulfidation, ensuring the stability of electrical connections during long-term use, and significantly extending product maintenance cycles and overall lifespan.

5. Widely Applicable and Withstands Harsh Environments

Copper belt safety caps can be widely used in various circuit breakers, high-voltage/low-voltage fuses, power distribution protection devices, and other electrical equipment. Their material and structural design allows them to withstand high and low temperature cycling shocks ranging from -40℃ to +125℃ and even wider, without deformation or cracking due to thermal expansion and contraction. They maintain stable performance even in harsh environments such as coastal high-salt spray and industrial high-pollution environments, demonstrating excellent environmental adaptability and durability.

Using high-quality electrolytic copper strip as the base material, the copper belt safety cap integrates precision manufacturing and surface treatment technologies, not only improving the product's thermal conductivity, structural strength, and safety, but also fundamentally solving the pain points of traditional covers being prone to aging, corrosion, and failure. It is not only the "shell" of the fuse, but also the "first line of defense" ensuring the safe operation of the circuit. In power systems that pursue high reliability, long lifespan, and high safety standards, this design undoubtedly represents a model of durability and technological progress, injecting solid strength into the stable operation of modern power infrastructure.