How does high-precision copper strip improve the conductivity of electronic components?

Release Time : 2025-10-20

With the increasing miniaturization and performance of modern electronic devices, the material selection of every tiny component has become crucial. The performance of electronic components depends not only on circuit design and chip technology, but also on the quality of the underlying materials. High-precision copper strip, as a key conductive material, is quietly playing an irreplaceable role. It not only serves as a "conduit" for electrical current but also as the "behind-the-scenes hero" that ensures the efficient and stable operation of electronic devices.

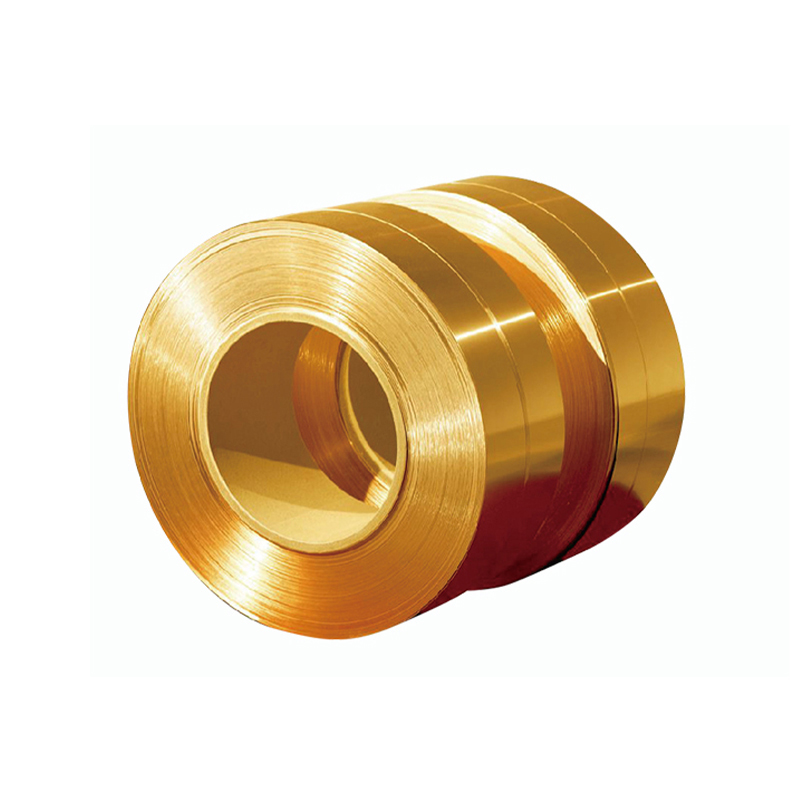

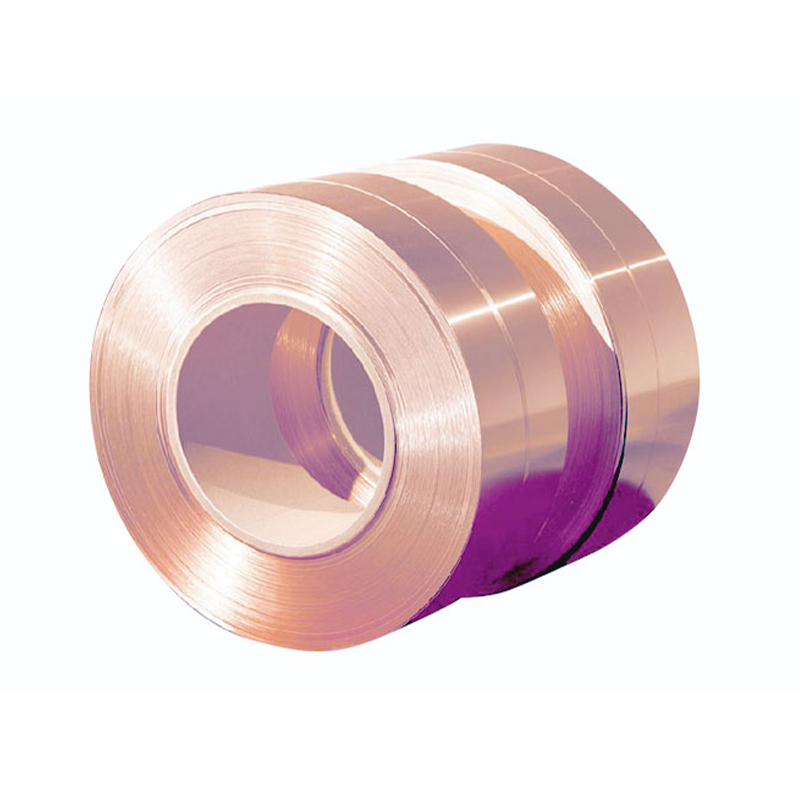

The quality of electrical conductivity is directly related to the operating efficiency, heat management, and signal transmission quality of electronic components. While traditional copper materials offer excellent conductivity, their overall performance is often affected by uneven thickness, rough surfaces, or high levels of impurities in precision electronics applications. High-precision copper strip, however, utilizes advanced smelting, rolling, and surface treatment processes to achieve a high degree of uniformity in material purity, geometric accuracy, and physical properties, significantly improving conductivity.

Firstly, high-precision copper strip's material purity and dense, uniform internal structure mean that electrons encounter less resistance as they pass through the material, ensuring smoother current transmission. This low impedance is particularly important in high-frequency or high-current environments. It effectively reduces energy loss and avoids local overheating caused by excessive resistance, thereby improving component efficiency and service life.

Secondly, high-precision copper strip features extremely precise dimensional control. Thickness, width, and edge smoothness are all achieved to micron-level precision. This highly consistent geometry ensures tighter and more stable contact between the copper strip and the component. In critical locations such as connectors, lead frames, and battery tabs, this precise fit not only reduces contact resistance but also avoids uneven current distribution caused by gaps or misalignment, ensuring efficient and uniform power transmission.

Furthermore, high-precision copper strip boasts exceptional surface quality. The specially treated surface is smooth and flat, free of oxidation, scratches, and burrs. This surface not only facilitates subsequent electroplating, soldering, and bonding processes, but also reduces electron scattering and loss during transmission. In high-speed signal transmission or precision sensing applications, this low-interference, highly stable conductive interface helps maintain signal integrity and improve device response speed and accuracy.

In practical applications, high-precision copper strip is widely used in key components such as integrated circuit lead frames, power module electrodes, flexible circuit connectors, and current collectors for new energy batteries. These components place extremely stringent demands on conductive materials—not only must they conduct electricity well, but they must also be fatigue-resistant, easy to process, and corrosion-resistant. High-precision copper strip, with its excellent comprehensive performance, perfectly meets these demands. For example, in power devices, it can quickly conduct high currents without overheating; in microsensors, it ensures the lossless transmission of weak signals; and in wearable devices, it can withstand repeated bending while maintaining stable conductivity.

Notably, the excellent conductivity of high-precision copper strip is not isolated; rather, it complements its excellent mechanical properties and processability. It possesses both sufficient strength to support the structure and good ductility to facilitate stamping, bending, and forming. This combination of rigidity and flexibility enables manufacturers to design and mass-produce complex structures without sacrificing performance, further driving the development of higher levels of integration in electronic components.

With the rapid development of emerging industries such as 5G communications, artificial intelligence, new energy vehicles, and the Internet of Things, performance requirements for electronic components are constantly increasing. High-precision copper strip, serving as a bridge connecting "electricity" and "intelligence," is supporting the underlying architecture of modern technology with its exceptional electrical conductivity. While inconspicuous, it is ubiquitous; seemingly ordinary, it carries the precise rhythm of electric current.

In short, high-precision copper strip, through its multiple advantages—pure material, precise dimensions, excellent surface quality, and stable structure—fundamentally optimizes the electrical paths of electronic components. It not only improves power transmission efficiency but also enhances device reliability and responsiveness. In the world of electronics, which strives for ultimate performance, high-precision copper strip is an indispensable "cornerstone," silently illuminating every pulse of signal and every intelligent response.

The quality of electrical conductivity is directly related to the operating efficiency, heat management, and signal transmission quality of electronic components. While traditional copper materials offer excellent conductivity, their overall performance is often affected by uneven thickness, rough surfaces, or high levels of impurities in precision electronics applications. High-precision copper strip, however, utilizes advanced smelting, rolling, and surface treatment processes to achieve a high degree of uniformity in material purity, geometric accuracy, and physical properties, significantly improving conductivity.

Firstly, high-precision copper strip's material purity and dense, uniform internal structure mean that electrons encounter less resistance as they pass through the material, ensuring smoother current transmission. This low impedance is particularly important in high-frequency or high-current environments. It effectively reduces energy loss and avoids local overheating caused by excessive resistance, thereby improving component efficiency and service life.

Secondly, high-precision copper strip features extremely precise dimensional control. Thickness, width, and edge smoothness are all achieved to micron-level precision. This highly consistent geometry ensures tighter and more stable contact between the copper strip and the component. In critical locations such as connectors, lead frames, and battery tabs, this precise fit not only reduces contact resistance but also avoids uneven current distribution caused by gaps or misalignment, ensuring efficient and uniform power transmission.

Furthermore, high-precision copper strip boasts exceptional surface quality. The specially treated surface is smooth and flat, free of oxidation, scratches, and burrs. This surface not only facilitates subsequent electroplating, soldering, and bonding processes, but also reduces electron scattering and loss during transmission. In high-speed signal transmission or precision sensing applications, this low-interference, highly stable conductive interface helps maintain signal integrity and improve device response speed and accuracy.

In practical applications, high-precision copper strip is widely used in key components such as integrated circuit lead frames, power module electrodes, flexible circuit connectors, and current collectors for new energy batteries. These components place extremely stringent demands on conductive materials—not only must they conduct electricity well, but they must also be fatigue-resistant, easy to process, and corrosion-resistant. High-precision copper strip, with its excellent comprehensive performance, perfectly meets these demands. For example, in power devices, it can quickly conduct high currents without overheating; in microsensors, it ensures the lossless transmission of weak signals; and in wearable devices, it can withstand repeated bending while maintaining stable conductivity.

Notably, the excellent conductivity of high-precision copper strip is not isolated; rather, it complements its excellent mechanical properties and processability. It possesses both sufficient strength to support the structure and good ductility to facilitate stamping, bending, and forming. This combination of rigidity and flexibility enables manufacturers to design and mass-produce complex structures without sacrificing performance, further driving the development of higher levels of integration in electronic components.

With the rapid development of emerging industries such as 5G communications, artificial intelligence, new energy vehicles, and the Internet of Things, performance requirements for electronic components are constantly increasing. High-precision copper strip, serving as a bridge connecting "electricity" and "intelligence," is supporting the underlying architecture of modern technology with its exceptional electrical conductivity. While inconspicuous, it is ubiquitous; seemingly ordinary, it carries the precise rhythm of electric current.

In short, high-precision copper strip, through its multiple advantages—pure material, precise dimensions, excellent surface quality, and stable structure—fundamentally optimizes the electrical paths of electronic components. It not only improves power transmission efficiency but also enhances device reliability and responsiveness. In the world of electronics, which strives for ultimate performance, high-precision copper strip is an indispensable "cornerstone," silently illuminating every pulse of signal and every intelligent response.