How can the electrical insulation performance of a copper tape connector be ensured under high voltage conditions?

Release Time : 2025-11-03

In high-voltage environments, the stable electrical insulation performance of copper tape connectors is the core guarantee for their safe and reliable operation. Because high-voltage environments place higher demands on the voltage resistance, aging resistance, and environmental adaptability of insulating materials, a comprehensive protection system must be constructed from multiple dimensions, including material selection, structural design, process control, and environmental protection, to ensure the stability of the copper tape connector's insulation performance during long-term high-voltage operation.

Insulating materials are the first line of defense for copper tape connectors against high voltage, requiring the selection of materials with high voltage resistance and stable dielectric properties. High-performance polymers such as silicone rubber and polytetrafluoroethylene (PTFE) are commonly used insulating media for high-voltage copper tape connectors due to their excellent insulation strength, arc resistance, and aging resistance. These materials not only maintain low dielectric loss under high voltage, reducing energy loss, but also effectively suppress partial discharge, avoiding the risk of short circuits caused by insulation breakdown. Simultaneously, the materials must pass temperature resistance tests to ensure that they do not soften, deform, or decompose in high-temperature environments, thereby maintaining the structural integrity of the insulation layer.

Structural design has a decisive influence on the insulation performance of copper tape connectors. Optimizing conductor spacing, increasing insulation thickness, and employing multi-layer shielding structures can significantly improve the withstand voltage of connectors. For example, adding air gaps between conductors or filling with high-dielectric-constant insulating materials can enhance the uniformity of the electric field distribution and reduce the risk of breakdown caused by localized electric field concentration. Furthermore, using an integrated molding process to tightly bond the insulation layer to the conductors avoids leakage risks caused by assembly gaps, further improving insulation reliability.

The precision of the manufacturing process directly affects the insulation performance of the copper tape connector. During production, the injection temperature, pressure, and curing time of the insulating material must be strictly controlled to ensure that the insulation layer is free of defects such as bubbles and cracks. Simultaneously, the conductor surface must undergo polishing and plating treatments to reduce contact resistance and minimize insulation aging caused by localized overheating. In addition, connecting the conductor and insulation layer using precision processes such as laser welding or ultrasonic welding can avoid insulation layer damage that may occur with traditional mechanical connections, thereby improving overall insulation strength.

Environmental adaptability is crucial for the copper tape connector to maintain stable insulation performance under high-voltage environments. For high-temperature environments, high-temperature resistant insulation materials must be selected, and heat dissipation structures, such as heat sinks or ventilation channels, should be added to the design to reduce the temperature rise of the connector during operation. For humid environments, a sealed design, such as rubber sealing rings or potting processes, is required to prevent moisture intrusion and subsequent degradation of insulation performance. Simultaneously, in corrosive gas environments, the conductors and insulation layers must undergo anti-corrosion treatment, such as nickel plating, zinc plating, or coating with anti-corrosion coatings, to extend the connector's service life.

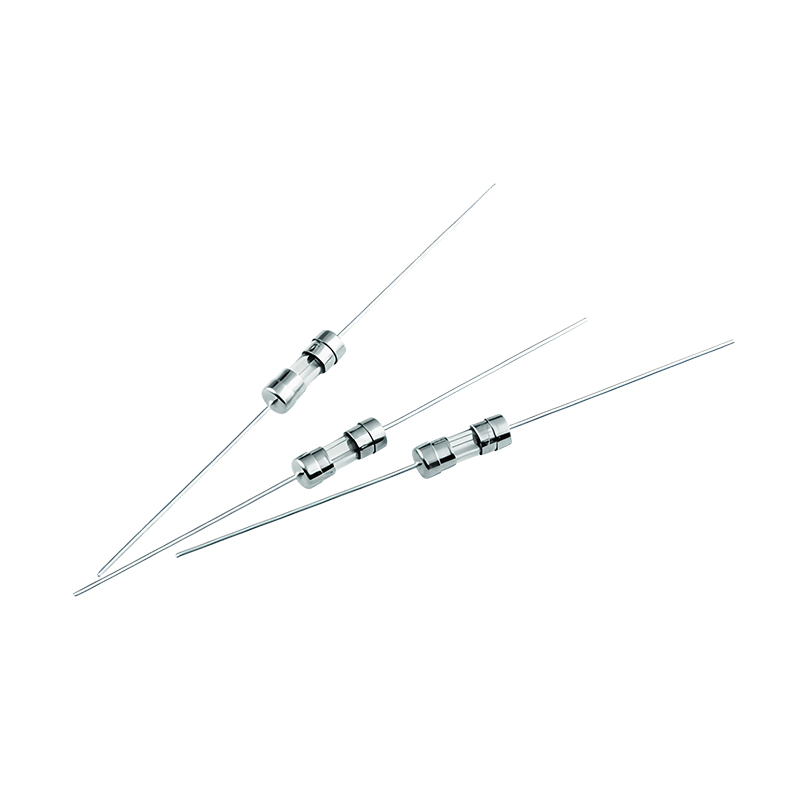

During long-term operation, the insulation performance of copper tape connectors may gradually deteriorate due to material aging, environmental corrosion, or mechanical stress. Therefore, a regular inspection and maintenance mechanism is necessary. Insulation defects should be detected promptly and repair measures taken through methods such as insulation resistance testing, withstand voltage testing, and partial discharge detection. For example, severely aged insulation layers should be replaced, or conductors with poor contact should be reconnected to restore the connector's insulation performance.

Stable insulation performance of copper tape connectors under high-voltage environments requires synergistic optimization of materials, structure, processes, environment, and maintenance. By selecting high-performance insulating materials, optimizing structural design, strictly controlling manufacturing processes, enhancing environmental adaptability, and establishing a regular testing mechanism, the insulation reliability of copper strip connectors under high-voltage environments can be effectively improved, providing safe and stable electrical connection solutions for fields such as power transmission, industrial automation, and new energy.