How to avoid edge cracks in the production of high precision brass strip?

Release Time : 2025-10-08

In the production of high-precision brass strip, preventing edge cracks requires a coordinated approach encompassing multiple steps, including alloy composition optimization, melting and casting process control, rolling parameter adjustment, and metallographic structure improvement. Edge cracks are primarily caused by raw material impurity segregation, rolling stress concentration, and metallographic defects. Systematic process control is essential for reducing the risk of cracking.

Raw material quality is fundamental to preventing edge cracks. In high-precision brass strip production, excessive lead content in raw materials can lead to segregation at grain boundaries, weakening intergranular bonding and potentially inducing intergranular cracking under rolling stress. Therefore, strict raw material purity control is crucial, particularly minimizing the content of harmful impurities such as lead and iron. For example, when using vacuum melting or medium-frequency induction furnaces, adding a capping agent to isolate the material from air to prevent oxidation and burnout, and using nitrogen or argon refining to remove inclusions can significantly reduce impurity levels and mitigate the risk of grain boundary weakening.

The melting and casting process is crucial to achieving uniform grain structure. During horizontal or upward continuous casting, insufficient cooling rates can easily lead to the formation of coarse columnar grains in the ingot, resulting in uneven deformation during subsequent rolling and tensile stress concentration at the edges. By optimizing the mold water temperature and casting speed—for example, maintaining the mold water temperature within a reasonable range and maintaining a moderate casting speed—grains can be refined to a smaller average size and reduce grain boundary defects. Furthermore, homogenization annealing immediately after casting can eliminate dendritic segregation, further improving hot rolling processability and preventing edge cracking caused by uneven microstructure.

Rolling process parameters must be precisely adjusted according to material properties. During high-precision brass strip cold rolling, excessive reductions, especially in the later stages of precision rolling, can lead to tensile stresses at the edges due to restricted flow, causing fine cracks. Using multiple passes with low reductions, such as moderate reductions in the initial pass and even lower reductions in the later precision rolling passes, can prevent excessive work hardening. Optimizing roll crown and bending force is also crucial. Appropriately reducing roll crown or adjusting bending force can balance deformation between the edge and center metal, reduce tensile stress at the edge, and thus inhibit crack propagation.

Metallurgical structure control is key to preventing edge cracks. Adding trace amounts of rare earth elements during smelting, such as rare earths and lead, forms high-melting-point compounds that preferentially precipitate during alloy crystallization, forming non-spontaneous nuclei. This refines the grain size and increases the number of grain boundaries, reducing the lead content per grain boundary. This increased number of grain boundaries disperses stress, preventing localized stress concentrations. Furthermore, rare earth compounds at grain boundaries enhance grain boundary strength, creating a "grain boundary strengthening" effect that effectively prevents intergranular cracking.

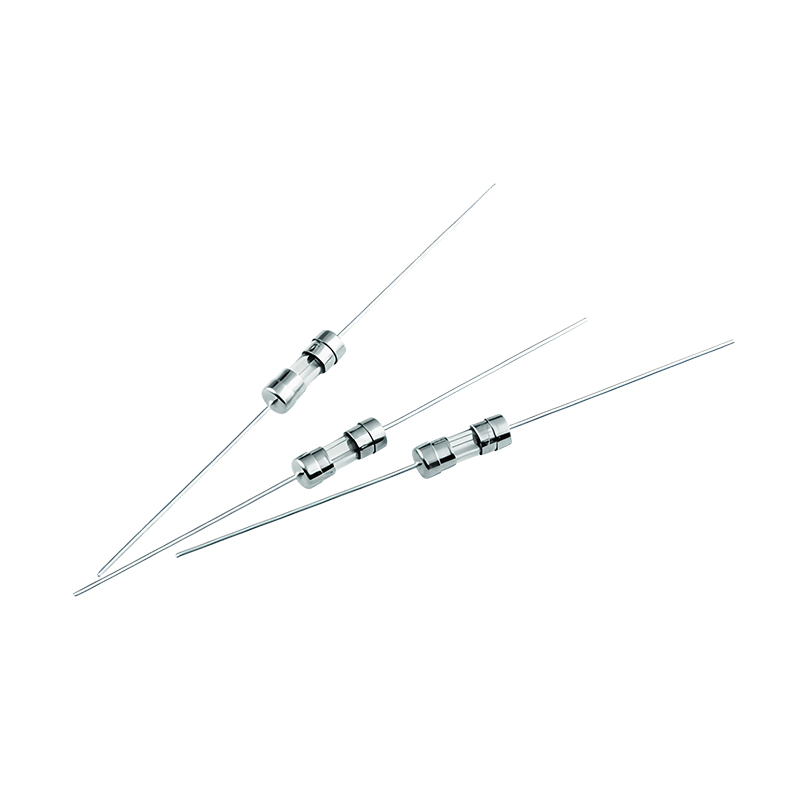

Heat treatment plays a key role in eliminating internal stress and stabilizing the microstructure. If annealing is not performed promptly after cold rolling, the accumulation of internal stresses can lead to spontaneous edge cracking. Intermediate annealing, at a moderate temperature and with a reasonable holding time, can eliminate cold rolling work hardening and restore plasticity. For high-zinc brass, the annealing temperature should be kept to the lower limit to prevent high-temperature dezincification, which can lead to surface "pitted" defects. Finished product annealing should be selected based on the intended use. For example, low-temperature annealing only relieves stress without changing the work-hardened state, making it suitable for applications requiring high hardness.

Surface treatment and edge processing are also crucial. During pickling and descaling, excessive acid concentration or prolonged pickling can lead to over-picking and dezincification of the edges, reducing edge strength. Using a mixture of sulfuric acid and hydrochloric acid, with controlled concentration and temperature, effectively removes oxide scale without damaging the substrate. During slitting, use high-precision circular shears or laser slitting machines to control edge burrs, and use multi-roll straightening machines to eliminate wavy or camber, ensuring edge flatness and avoiding stress concentration caused by edge defects.