How do stamping and cutting processes ensure smooth, burr-free edges on copper button products?

Release Time : 2025-08-28

As the finishing touch of high-end apparel, luggage, and leather goods, copper buttons' quality lies not only in the precious materials and exquisite design, but also in the meticulous attention to detail. Edge smoothness is a crucial indicator of the precision of a copper button's craftsmanship. Burrs, flash, or irregular cuts not only affect the tactile feel but can also scratch the fabric or the wearer's skin, diminishing the overall quality. Therefore, precise control of the stamping and cutting processes during the manufacturing process is crucial to ensuring smooth, flawless edges.

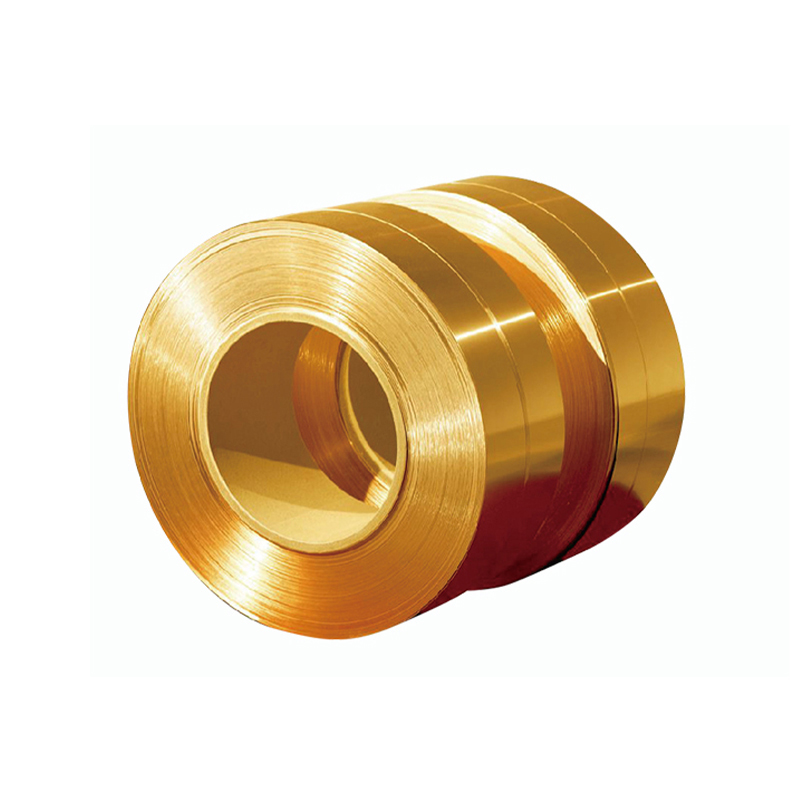

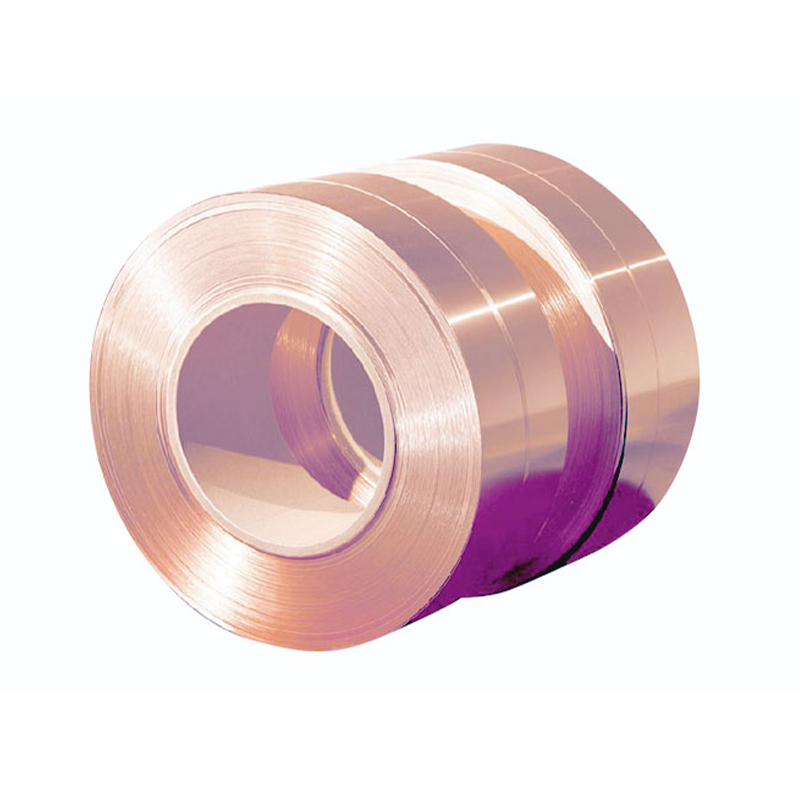

Stamping is the first step in forming a copper button. High-quality copper strip is fed into a high-precision die, where powerful and steady pressure instantly shapes the contours. This seemingly rough process places extremely high demands on die machining accuracy, steel hardness, and clearances. The die's cutting edge must be finely polished to a mirror-like finish, and the gap between the upper and lower dies must be uniform. If the gap is too large, the material will be squeezed and deformed under stress, forming burrs. If the gap is too small, it can easily cause edge wear or even cracking. Modern stamping processes often use CNC machining technology to create dies, ensuring that every curved surface and straight line is perfectly aligned, eliminating burrs from the source.

During the stamping process, the material flow direction and force distribution are carefully designed. Although copper strip has good ductility, it can still cause minor tears or curling when subjected to severe deformation. To this end, the die's guiding structure and pressure profile must be optimized to ensure smooth expansion of the copper material under stress and avoid localized stress concentrations. Matching stamping speed and pressure is also crucial: too fast can cause material fracture, while too slow can affect efficiency and edge quality. Experienced technicians fine-tune parameters based on the thickness and hardness of the copper strip to ensure a clean, precise stamping every time.

The cutting process further refines the contours. Laser cutting or precision cutting equipment is widely used for buttons with complex shapes or those requiring secondary processing. Laser cutting uses a high-energy beam to precisely ablate material, creating a controlled path and fine cuts. It is particularly well-suited for processing curved, sharp-angled, or openwork designs. Its heat-affected zone is minimal, preventing discoloration or hardening of the surrounding copper. Mechanical cutting, on the other hand, relies on super-hard alloy tools, coupled with high rotational speeds and a steady feed rate, to achieve smooth cuts. In both methods, the stability of the equipment and the sharpness of the tool directly impact the final edge quality.

After initial shaping, buttons undergo deburring and polishing. Although stamping and cutting significantly reduce burrs, microscopic protrusions may still remain. Vibratory grinding, drum polishing, or hand finishing are then used to further remove any remaining burrs. The choice of abrasive media, timing, and pressure all require careful consideration: over-processing can damage the design, while under-processing may not completely remove imperfections. This process involves more than just physical polishing; it also requires a meticulous attention to detail.

Surface treatments such as electroplating or brushing can also mask or enhance edge texture to a certain extent. The electroplating layer evenly covers the edges, filling minor irregularities and creating a smoother contour. The brushing process, through directional friction, creates a consistent grain pattern along the edges, creating a more harmonious visual effect. However, these subsequent treatments cannot correct severe burrs, so the initial quality of stamping and cutting remains paramount.

Ultimately, a smooth-edged copper button is the result of the synergy of materials, molds, equipment, and craftsmanship. It slides effortlessly across your fingertips, adheres gently and seamlessly to fabrics, quietly demonstrating the rigor and meticulous craftsmanship behind its manufacturing. This meticulous pursuit of edges is not merely aesthetically pleasing; it is a commitment to quality—upholding visible standards in every invisible detail.

Stamping is the first step in forming a copper button. High-quality copper strip is fed into a high-precision die, where powerful and steady pressure instantly shapes the contours. This seemingly rough process places extremely high demands on die machining accuracy, steel hardness, and clearances. The die's cutting edge must be finely polished to a mirror-like finish, and the gap between the upper and lower dies must be uniform. If the gap is too large, the material will be squeezed and deformed under stress, forming burrs. If the gap is too small, it can easily cause edge wear or even cracking. Modern stamping processes often use CNC machining technology to create dies, ensuring that every curved surface and straight line is perfectly aligned, eliminating burrs from the source.

During the stamping process, the material flow direction and force distribution are carefully designed. Although copper strip has good ductility, it can still cause minor tears or curling when subjected to severe deformation. To this end, the die's guiding structure and pressure profile must be optimized to ensure smooth expansion of the copper material under stress and avoid localized stress concentrations. Matching stamping speed and pressure is also crucial: too fast can cause material fracture, while too slow can affect efficiency and edge quality. Experienced technicians fine-tune parameters based on the thickness and hardness of the copper strip to ensure a clean, precise stamping every time.

The cutting process further refines the contours. Laser cutting or precision cutting equipment is widely used for buttons with complex shapes or those requiring secondary processing. Laser cutting uses a high-energy beam to precisely ablate material, creating a controlled path and fine cuts. It is particularly well-suited for processing curved, sharp-angled, or openwork designs. Its heat-affected zone is minimal, preventing discoloration or hardening of the surrounding copper. Mechanical cutting, on the other hand, relies on super-hard alloy tools, coupled with high rotational speeds and a steady feed rate, to achieve smooth cuts. In both methods, the stability of the equipment and the sharpness of the tool directly impact the final edge quality.

After initial shaping, buttons undergo deburring and polishing. Although stamping and cutting significantly reduce burrs, microscopic protrusions may still remain. Vibratory grinding, drum polishing, or hand finishing are then used to further remove any remaining burrs. The choice of abrasive media, timing, and pressure all require careful consideration: over-processing can damage the design, while under-processing may not completely remove imperfections. This process involves more than just physical polishing; it also requires a meticulous attention to detail.

Surface treatments such as electroplating or brushing can also mask or enhance edge texture to a certain extent. The electroplating layer evenly covers the edges, filling minor irregularities and creating a smoother contour. The brushing process, through directional friction, creates a consistent grain pattern along the edges, creating a more harmonious visual effect. However, these subsequent treatments cannot correct severe burrs, so the initial quality of stamping and cutting remains paramount.

Ultimately, a smooth-edged copper button is the result of the synergy of materials, molds, equipment, and craftsmanship. It slides effortlessly across your fingertips, adheres gently and seamlessly to fabrics, quietly demonstrating the rigor and meticulous craftsmanship behind its manufacturing. This meticulous pursuit of edges is not merely aesthetically pleasing; it is a commitment to quality—upholding visible standards in every invisible detail.