How does high-precision copper strip meet the stringent requirements for conductivity, ductility, and thickness uniformity in lithium battery tabs?

Release Time : 2025-09-11

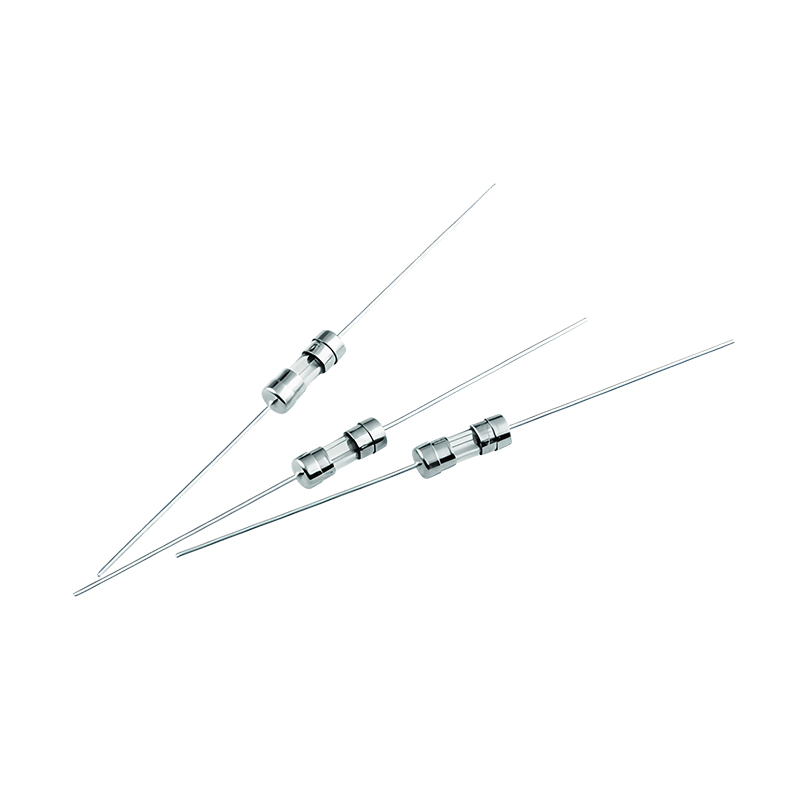

In modern lithium battery manufacturing, tabs serve as the critical conductive pathway connecting the active materials within the cell with the external circuitry. Their performance is directly related to the battery's charge and discharge efficiency, cycle life, and safety and stability. The high-precision copper strip used to manufacture the tabs is the cornerstone material for this critical component. It must not only possess excellent conductivity but also maintain excellent ductility and highly consistent thickness control within an extremely thin form factor to withstand the demanding challenges of high-speed stamping, precision welding, and long-term service in lithium battery production.

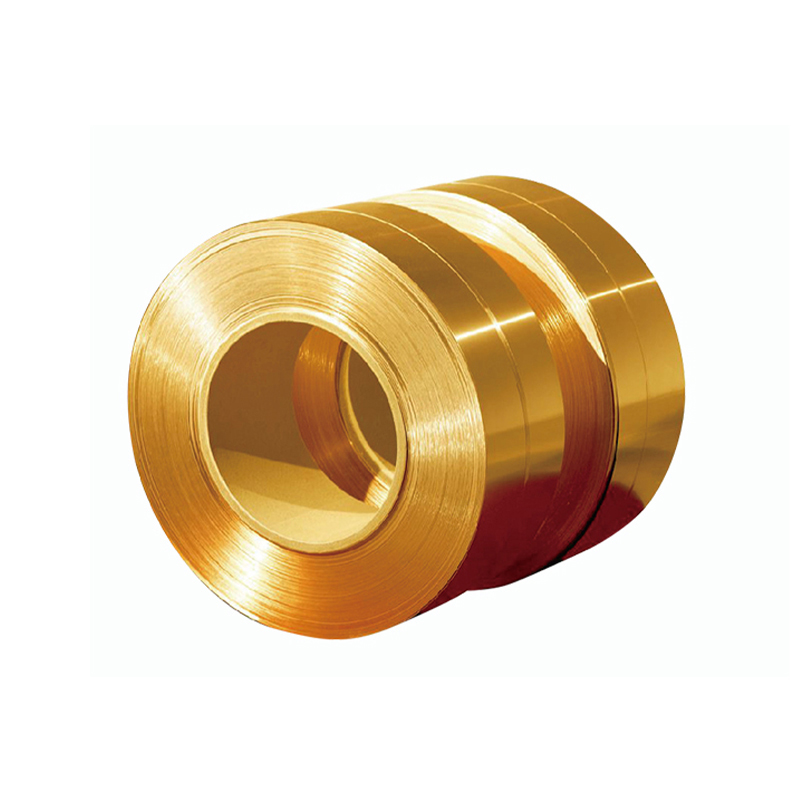

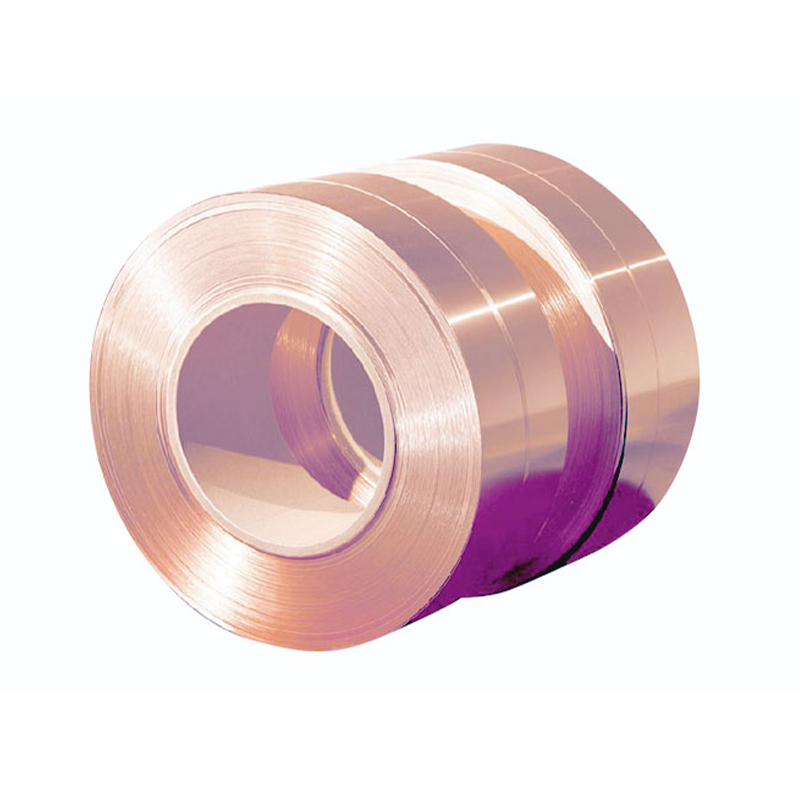

Conductivity is the most critical performance metric for high-precision copper strip. Lithium batteries require high current charging and discharging during operation. If the tab material's resistance is too high, it will increase energy loss, exacerbate localized heating, and even lead to the risk of thermal runaway. High-precision copper strip is made from high-purity electrolytic copper, undergoing rigorous purification and casting processes to minimize residual impurities. The pure lattice structure provides an unimpeded transmission path for electrons, ensuring efficient current flow through the tabs, reducing internal resistance and improving overall battery efficiency. This inherent conductivity ensures battery stability even at high power output, providing reliable support for applications such as power tools and new energy vehicles.

Ductility determines the copper strip's plasticity and yield during subsequent processing. Tabs are typically formed continuously from a copper strip coil using a high-speed stamping process, which subjects the material to severe localized stretching and bending. Excessive brittleness can easily lead to microcracks or burrs on the punched edges, compromising welding quality and even causing strip breakage and downtime. High-precision copper strip achieves fine and uniform grain distribution through precisely controlled cold rolling and annealing, endowing the material with excellent plastic deformation capabilities. It can be precisely formed using complex dies, resulting in smooth, complete edges without cracking or delamination. Furthermore, its optimal balance of hardness and flexibility prevents breakage and wrinkling during winding and conveying, ensuring smooth continuous production.

Thickness uniformity is a key quality metric for high-precision copper strip. Lithium battery tabs require extremely high dimensional accuracy. Any slight thickness fluctuation can affect the consistency of welding between the tab and the aluminum casing or cover plate, resulting in cold welds, over-welding, or poor sealing. High-precision copper strip utilizes an advanced profile control system during the rolling process, monitoring and adjusting roller pressure and tension in real time to ensure highly consistent thickness throughout the entire roll. Horizontal and longitudinal tolerances are strictly controlled within extremely narrow limits to avoid uneven resistance or stress concentration caused by localized thickness variations. This extreme dimensional stability provides a reliable foundation for automated welding, ensuring that every battery tab connection meets the same high-quality standards.

Surface quality is also crucial. The copper strip surface must be clean and flat, free of oxidation, scratches, and foreign matter to prevent the formation of pores or inclusions during welding. Inert atmosphere protection or in-line cleaning techniques are used during production to prevent surface contamination. Edges are precisely trimmed to eliminate burrs and flanging, preventing scratches on the mold or damage to the insulation layer during high-speed feeding. These meticulous attention to detail contribute to the comprehensive reliability of the tab material.

From the source material to the finished tab, high-precision copper strip carries the underlying logic for improving lithium battery performance. It's not just a conductive carrier; it embodies the fusion of precision manufacturing and materials science. Its stable performance supports battery companies in their pursuit of higher energy density, longer cycle life, and safer operation. It's this "invisible precision" that makes every charge and discharge more efficient, reliable, and secure.

Conductivity is the most critical performance metric for high-precision copper strip. Lithium batteries require high current charging and discharging during operation. If the tab material's resistance is too high, it will increase energy loss, exacerbate localized heating, and even lead to the risk of thermal runaway. High-precision copper strip is made from high-purity electrolytic copper, undergoing rigorous purification and casting processes to minimize residual impurities. The pure lattice structure provides an unimpeded transmission path for electrons, ensuring efficient current flow through the tabs, reducing internal resistance and improving overall battery efficiency. This inherent conductivity ensures battery stability even at high power output, providing reliable support for applications such as power tools and new energy vehicles.

Ductility determines the copper strip's plasticity and yield during subsequent processing. Tabs are typically formed continuously from a copper strip coil using a high-speed stamping process, which subjects the material to severe localized stretching and bending. Excessive brittleness can easily lead to microcracks or burrs on the punched edges, compromising welding quality and even causing strip breakage and downtime. High-precision copper strip achieves fine and uniform grain distribution through precisely controlled cold rolling and annealing, endowing the material with excellent plastic deformation capabilities. It can be precisely formed using complex dies, resulting in smooth, complete edges without cracking or delamination. Furthermore, its optimal balance of hardness and flexibility prevents breakage and wrinkling during winding and conveying, ensuring smooth continuous production.

Thickness uniformity is a key quality metric for high-precision copper strip. Lithium battery tabs require extremely high dimensional accuracy. Any slight thickness fluctuation can affect the consistency of welding between the tab and the aluminum casing or cover plate, resulting in cold welds, over-welding, or poor sealing. High-precision copper strip utilizes an advanced profile control system during the rolling process, monitoring and adjusting roller pressure and tension in real time to ensure highly consistent thickness throughout the entire roll. Horizontal and longitudinal tolerances are strictly controlled within extremely narrow limits to avoid uneven resistance or stress concentration caused by localized thickness variations. This extreme dimensional stability provides a reliable foundation for automated welding, ensuring that every battery tab connection meets the same high-quality standards.

Surface quality is also crucial. The copper strip surface must be clean and flat, free of oxidation, scratches, and foreign matter to prevent the formation of pores or inclusions during welding. Inert atmosphere protection or in-line cleaning techniques are used during production to prevent surface contamination. Edges are precisely trimmed to eliminate burrs and flanging, preventing scratches on the mold or damage to the insulation layer during high-speed feeding. These meticulous attention to detail contribute to the comprehensive reliability of the tab material.

From the source material to the finished tab, high-precision copper strip carries the underlying logic for improving lithium battery performance. It's not just a conductive carrier; it embodies the fusion of precision manufacturing and materials science. Its stable performance supports battery companies in their pursuit of higher energy density, longer cycle life, and safer operation. It's this "invisible precision" that makes every charge and discharge more efficient, reliable, and secure.