How does the copper tape connector achieve efficient heat dissipation?

Release Time : 2025-08-15

In the sophisticated world of modern electrical and electronic devices, the copper tape connector, with its unique charm, is redefining the aesthetics and performance of conductive connections. No longer the cold, bulky metal connector of the past, it has evolved into a critical component that blends exceptional conductivity, structural strength, and the beauty of industrial design. It quietly supports the stable operation of everything from new energy vehicles and rail transit to high-end industrial equipment, smart grids, and even precision electronic instruments, becoming a "golden bridge" for efficient and reliable energy and signal transmission.

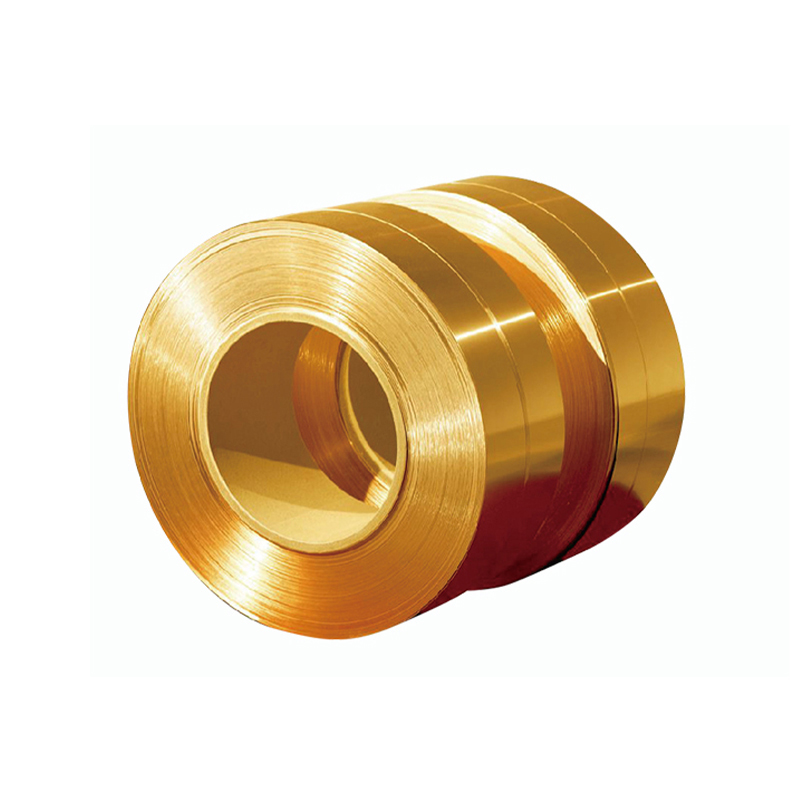

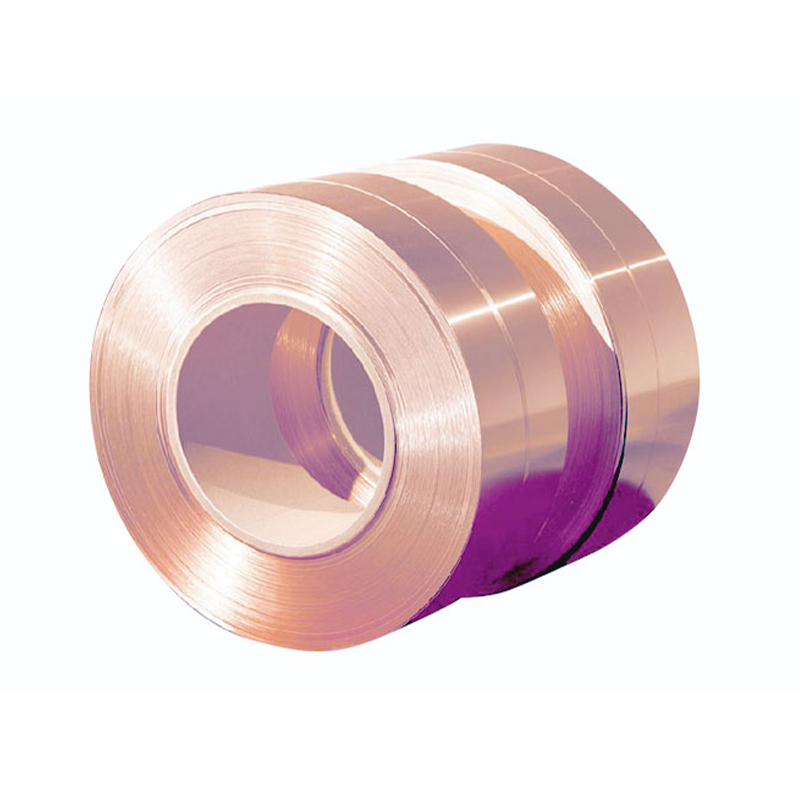

Its inherent beauty is rooted first and foremost in the purity and refinement of its materials. Selected high-purity oxygen-free copper (OFC) as its core base material ensures near-perfect conductivity, minimizing energy loss during current transmission and laying a solid foundation for efficient system operation. However, the true innovation lies in the revolutionary reshaping of copper's form. Eliminating the limitations of traditional cables or bulk connectors, the copper tape connector utilizes precision rolling or stamping processes to stretch copper into a flat ribbon structure of precisely defined thickness and width. This design not only significantly increases the conductor's surface area, optimizing heat dissipation and effectively preventing localized overheating, but also provides the connector with unprecedented structural rigidity and spatial adaptability. Its meticulous surface treatment—from a mirror-like polish to corrosion-resistant tin, silver, or even gold plating—not only enhances its resistance to oxidation and environmental corrosion, extending its service life, but also creates a restrained and professional metallic luster within the device, creating a refined aesthetic in the industrial landscape.

The essence of innovation lies in the intelligent structural design and functional integration. The flattened copper strip enables stable transmission of high currents in a minimal footprint, perfectly aligning with the trend toward miniaturization and high-density integration in modern devices. Like a flexible "electrical spine," it can bend and twist effortlessly, adapting to complex three-dimensional wiring paths, effectively solving wiring challenges in confined spaces and significantly enhancing the flexibility and aesthetics of internal device layouts. More importantly, innovative connection technologies are widely utilized: Precision stamping and forming techniques enable the integration of mounting holes, positioning clips, heat sink fins, and even sensor interfaces directly into the copper strip. Advanced welding (such as laser welding and ultrasonic welding) or crimping techniques ensure low resistance, high reliability, and long-term stability at the connection points, eliminating the risk of loosening associated with traditional bolted connections. Some high-end models even incorporate intelligent monitoring features. Integrated micro-sensors monitor temperature, current, and other parameters at the connection points in real time, providing data support for preventive maintenance and elevating passive connections into active, intelligent nodes.

The advantages of this innovation are comprehensive. In the new energy vehicle sector, the copper tape connector is the "lifeline" for connecting battery cells in series and parallel within a power battery pack. Its low impedance, high heat dissipation, and high reliability are directly related to the vehicle's power performance and safety. In rail transit, it carries the high currents of the traction system, and its robust structure and excellent vibration resistance ensure stable train operation. In data centers and 5G base stations, it provides efficient connections for high-power power modules, facilitating high-speed information flow. In wind turbines, it connects the generator and converter, ensuring stable operation in harsh environments. Its environmental impact is also crucial. Its high-purity copper is 100% recyclable, meeting the requirements of sustainable development.

The copper tape connector, with its refined material, innovative flat design, excellent electrical and heat dissipation performance, flexible spatial adaptability, and increasingly intelligent functional integration, transcends the scope of traditional connectors. It is not only a faithful carrier of current but also a concentrated embodiment of modern industrial precision, efficiency, reliability, and aesthetics. As countless such "golden bridges" silently transmit energy and information deep within the device, they together build a solid and elegant foundation for the modern technological world.

Its inherent beauty is rooted first and foremost in the purity and refinement of its materials. Selected high-purity oxygen-free copper (OFC) as its core base material ensures near-perfect conductivity, minimizing energy loss during current transmission and laying a solid foundation for efficient system operation. However, the true innovation lies in the revolutionary reshaping of copper's form. Eliminating the limitations of traditional cables or bulk connectors, the copper tape connector utilizes precision rolling or stamping processes to stretch copper into a flat ribbon structure of precisely defined thickness and width. This design not only significantly increases the conductor's surface area, optimizing heat dissipation and effectively preventing localized overheating, but also provides the connector with unprecedented structural rigidity and spatial adaptability. Its meticulous surface treatment—from a mirror-like polish to corrosion-resistant tin, silver, or even gold plating—not only enhances its resistance to oxidation and environmental corrosion, extending its service life, but also creates a restrained and professional metallic luster within the device, creating a refined aesthetic in the industrial landscape.

The essence of innovation lies in the intelligent structural design and functional integration. The flattened copper strip enables stable transmission of high currents in a minimal footprint, perfectly aligning with the trend toward miniaturization and high-density integration in modern devices. Like a flexible "electrical spine," it can bend and twist effortlessly, adapting to complex three-dimensional wiring paths, effectively solving wiring challenges in confined spaces and significantly enhancing the flexibility and aesthetics of internal device layouts. More importantly, innovative connection technologies are widely utilized: Precision stamping and forming techniques enable the integration of mounting holes, positioning clips, heat sink fins, and even sensor interfaces directly into the copper strip. Advanced welding (such as laser welding and ultrasonic welding) or crimping techniques ensure low resistance, high reliability, and long-term stability at the connection points, eliminating the risk of loosening associated with traditional bolted connections. Some high-end models even incorporate intelligent monitoring features. Integrated micro-sensors monitor temperature, current, and other parameters at the connection points in real time, providing data support for preventive maintenance and elevating passive connections into active, intelligent nodes.

The advantages of this innovation are comprehensive. In the new energy vehicle sector, the copper tape connector is the "lifeline" for connecting battery cells in series and parallel within a power battery pack. Its low impedance, high heat dissipation, and high reliability are directly related to the vehicle's power performance and safety. In rail transit, it carries the high currents of the traction system, and its robust structure and excellent vibration resistance ensure stable train operation. In data centers and 5G base stations, it provides efficient connections for high-power power modules, facilitating high-speed information flow. In wind turbines, it connects the generator and converter, ensuring stable operation in harsh environments. Its environmental impact is also crucial. Its high-purity copper is 100% recyclable, meeting the requirements of sustainable development.

The copper tape connector, with its refined material, innovative flat design, excellent electrical and heat dissipation performance, flexible spatial adaptability, and increasingly intelligent functional integration, transcends the scope of traditional connectors. It is not only a faithful carrier of current but also a concentrated embodiment of modern industrial precision, efficiency, reliability, and aesthetics. As countless such "golden bridges" silently transmit energy and information deep within the device, they together build a solid and elegant foundation for the modern technological world.