What physical advantages does high-purity copper tape offer in reducing resistive losses and improving current-carrying stability?

Release Time : 2025-07-31

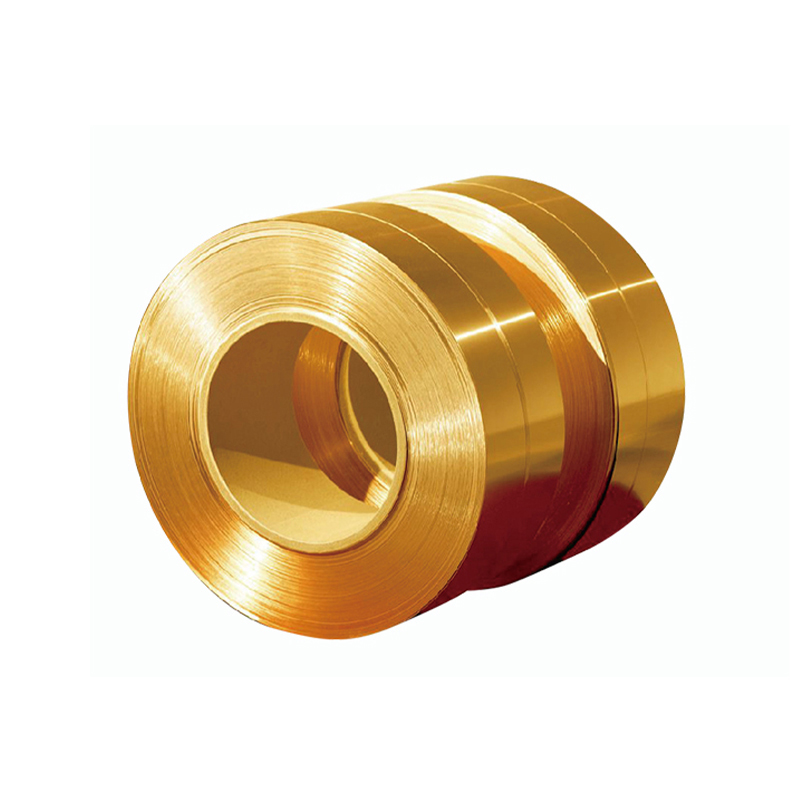

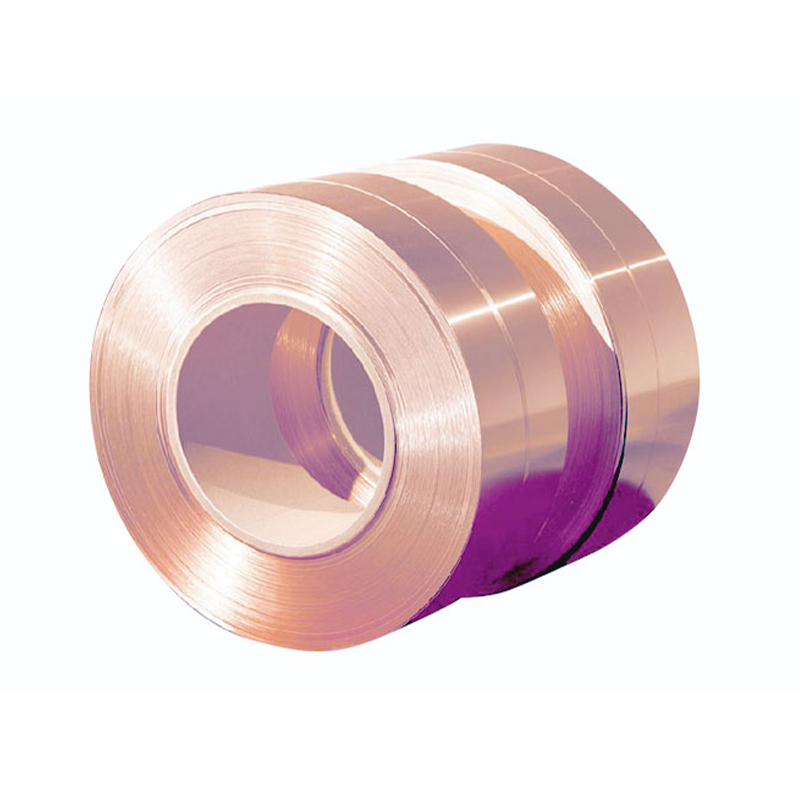

In the complex web of modern industrial and energy systems, stable transmission of power and signals is the lifeblood of efficient equipment operation. Within this invisible "neural network," the copper tape connector plays a crucial role. It's more than a simple splicing of conductors; it's a high-end connection solution that integrates material science, precision manufacturing, and engineering reliability. Using high-purity copper tape as a base material, it's formed in one piece through forging, precision cutting, and stamping, eliminating traditional welding processes. This eliminates the risks of loose connections, fractures, and thermal failure at the source, making it an indispensable "power bridge" for demanding applications such as industrial equipment, renewable energy power generation, energy storage systems, and high-voltage power distribution.

The core value of the copper tape connector lies in its dual pursuit of structural integrity and ultimate electrical performance. Traditional connection methods often rely on welding or bolting, which are susceptible to thermal expansion and contraction, vibration fatigue, or oxidative corrosion over long-term operation, leading to increased contact resistance, localized overheating, and even connection failure. The copper tape connector utilizes one-piece molding technology. A single block of high-purity electrolytic copper is forged and then directly stamped and cut into the desired shape, ensuring a continuous conductor path with no discontinuities and a uniform, dense internal lattice structure. This "solderless" manufacturing process fundamentally eliminates potential failures caused by solder joint aging, solder cracking, or interface contamination, ensuring the connector maintains stable low resistance and high conductivity throughout its lifecycle, effectively reducing energy loss and temperature rise, and improving overall system efficiency.

The innovation of the copper tape connector lies not only in its manufacturing process but also in its deep optimization of environmental tolerance and interface versatility. Copper inherently possesses excellent conductivity, high-temperature resistance, and fatigue resistance, but it can still oxidize in humid, salt-fog, or high-temperature environments, affecting contact performance. To address this, the connector surface is nickel-plated or tin-plated to create a dense protective layer. The nickel layer provides excellent wear resistance and oxidation resistance, making it suitable for frequent plugging and unplugging or high-vibration environments. The tin layer enhances solderability and low-temperature stability, preventing the growth of "tin whiskers" and ensuring long-term contact reliability. This surface engineering allows the connector to adapt to a wide range of geographical and climatic conditions, from polar wind farms to desert photovoltaic power plants. Furthermore, its flexible structural design allows customization in straight, bent, and multi-branch configurations. Interface dimensions and hole positions can be precisely matched to equipment requirements, enabling seamless integration with busbars, terminals, or modules, significantly enhancing adaptability in complex electrical layouts.

The copper tape connector demonstrates a deep understanding of long-term reliability and maintenance costs. In industrial automation, rail transit, data centers, or new energy conversion systems, any downtime caused by a connection failure can result in significant economic losses. The copper tape connector, with its maintenance-free design and long life, significantly reduces the complexity and potential risks of system operations. Its stable current-carrying capacity ensures safe operation under peak loads and transient surges, providing solid protection for critical equipment. For system integrators, the standardized, integrated design simplifies the installation process, reduces quality fluctuations associated with on-site welding or crimping, and improves the consistency and predictability of project delivery.

Even more thought-provoking is the strategic significance of copper tape connectors in promoting energy transformation and smart manufacturing upgrades. In wind turbine pitch systems, photovoltaic inverter DC busbars, and the series and parallel connections of electric vehicle battery packs, copper tape connectors carry high current, high frequency, and high-reliability transmission tasks. As power density continues to rise, the thermal management and electrical performance requirements for connectors are becoming increasingly stringent. With its low impedance, high heat dissipation efficiency, and excellent electromagnetic compatibility, copper tape connectors have become key components supporting the stable operation of high-power power electronics systems, contributing to the efficient conversion and utilization of clean energy.

Though simply formed from a metal strip, copper tape connectors embody a reverence for the essence of electricity and a challenge to the limits of engineering. They utilize a one-piece molding process to eliminate vulnerable points in connections, leverage the inherent properties of high-purity copper to transmit the purest current, and utilize surface coatings to resist the erosion of time. In an era of pursuit of high reliability, high efficiency, and sustainable energy, copper tape connectors are quietly but remarkably becoming the resilient "conductive backbone" of modern industry, silently supporting every surge of energy and the smooth operation of systems.

The core value of the copper tape connector lies in its dual pursuit of structural integrity and ultimate electrical performance. Traditional connection methods often rely on welding or bolting, which are susceptible to thermal expansion and contraction, vibration fatigue, or oxidative corrosion over long-term operation, leading to increased contact resistance, localized overheating, and even connection failure. The copper tape connector utilizes one-piece molding technology. A single block of high-purity electrolytic copper is forged and then directly stamped and cut into the desired shape, ensuring a continuous conductor path with no discontinuities and a uniform, dense internal lattice structure. This "solderless" manufacturing process fundamentally eliminates potential failures caused by solder joint aging, solder cracking, or interface contamination, ensuring the connector maintains stable low resistance and high conductivity throughout its lifecycle, effectively reducing energy loss and temperature rise, and improving overall system efficiency.

The innovation of the copper tape connector lies not only in its manufacturing process but also in its deep optimization of environmental tolerance and interface versatility. Copper inherently possesses excellent conductivity, high-temperature resistance, and fatigue resistance, but it can still oxidize in humid, salt-fog, or high-temperature environments, affecting contact performance. To address this, the connector surface is nickel-plated or tin-plated to create a dense protective layer. The nickel layer provides excellent wear resistance and oxidation resistance, making it suitable for frequent plugging and unplugging or high-vibration environments. The tin layer enhances solderability and low-temperature stability, preventing the growth of "tin whiskers" and ensuring long-term contact reliability. This surface engineering allows the connector to adapt to a wide range of geographical and climatic conditions, from polar wind farms to desert photovoltaic power plants. Furthermore, its flexible structural design allows customization in straight, bent, and multi-branch configurations. Interface dimensions and hole positions can be precisely matched to equipment requirements, enabling seamless integration with busbars, terminals, or modules, significantly enhancing adaptability in complex electrical layouts.

The copper tape connector demonstrates a deep understanding of long-term reliability and maintenance costs. In industrial automation, rail transit, data centers, or new energy conversion systems, any downtime caused by a connection failure can result in significant economic losses. The copper tape connector, with its maintenance-free design and long life, significantly reduces the complexity and potential risks of system operations. Its stable current-carrying capacity ensures safe operation under peak loads and transient surges, providing solid protection for critical equipment. For system integrators, the standardized, integrated design simplifies the installation process, reduces quality fluctuations associated with on-site welding or crimping, and improves the consistency and predictability of project delivery.

Even more thought-provoking is the strategic significance of copper tape connectors in promoting energy transformation and smart manufacturing upgrades. In wind turbine pitch systems, photovoltaic inverter DC busbars, and the series and parallel connections of electric vehicle battery packs, copper tape connectors carry high current, high frequency, and high-reliability transmission tasks. As power density continues to rise, the thermal management and electrical performance requirements for connectors are becoming increasingly stringent. With its low impedance, high heat dissipation efficiency, and excellent electromagnetic compatibility, copper tape connectors have become key components supporting the stable operation of high-power power electronics systems, contributing to the efficient conversion and utilization of clean energy.

Though simply formed from a metal strip, copper tape connectors embody a reverence for the essence of electricity and a challenge to the limits of engineering. They utilize a one-piece molding process to eliminate vulnerable points in connections, leverage the inherent properties of high-purity copper to transmit the purest current, and utilize surface coatings to resist the erosion of time. In an era of pursuit of high reliability, high efficiency, and sustainable energy, copper tape connectors are quietly but remarkably becoming the resilient "conductive backbone" of modern industry, silently supporting every surge of energy and the smooth operation of systems.