How does the copper belt safety cap provide fast and safe protection when the circuit is overloaded?

Release Time : 2025-07-15

1. Quick response: the perfect combination of copper's high thermal conductivity and moderate melting point

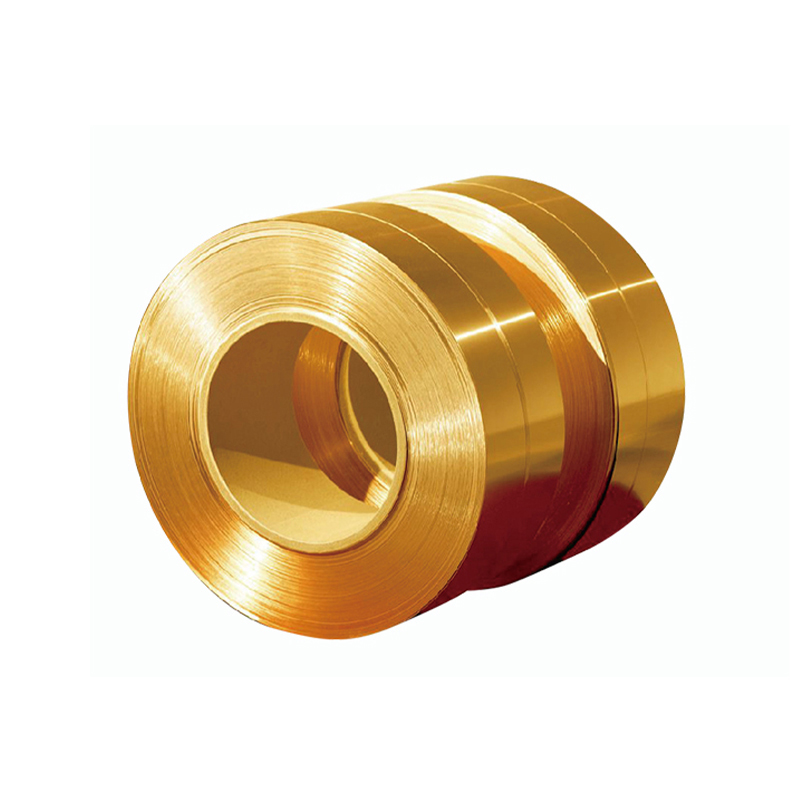

As a key component in modern circuit protection devices, the copper belt safety cap is made of high-quality electrolytic copper strip. Copper has excellent thermal conductivity and can quickly conduct the heat generated by the current to avoid abnormal temperature rise caused by local overheating. At the same time, copper has a moderate melting point (about 1083℃), and when the circuit is overloaded or short-circuited, it can quickly reach the melting temperature and achieve rapid power failure. This feature enables the copper belt safety cap to respond to the fault current within milliseconds, thereby effectively cutting off the power supply and preventing equipment damage or fire accidents.

2. Precision stamping process: weld-free structure improves stability and safety

The copper belt safety cap adopts precision stamping technology, and the entire structure has no welding points, avoiding problems such as cold welding, oxidation or weak structure that may exist in traditional welding processes. This integrated structure is more compact and stable, which not only enhances mechanical strength, but also improves electrical conductivity and thermal conduction efficiency. In the case of a sudden increase in current or high temperature, the copper belt safety cap can maintain structural integrity, ensure that the fusing process is controllable and splash-free, thereby improving the safety of the overall circuit protection.

3. Splash-free fusing: a key feature for achieving safe power off

In traditional fuses or circuit breakers, when the current is overloaded, the fusing process is often accompanied by metal splashing, which may cause secondary short circuits or arc discharges, posing safety hazards. The copper belt safety cap has fully considered this issue in its design. Its unique material properties and structural design prevent metal splashing when it is fusing. Copper maintains a relatively stable form during the melting process and does not form jet-like molten particles, thereby avoiding damage to surrounding electronic components or operators, and achieving a true "safe power off".

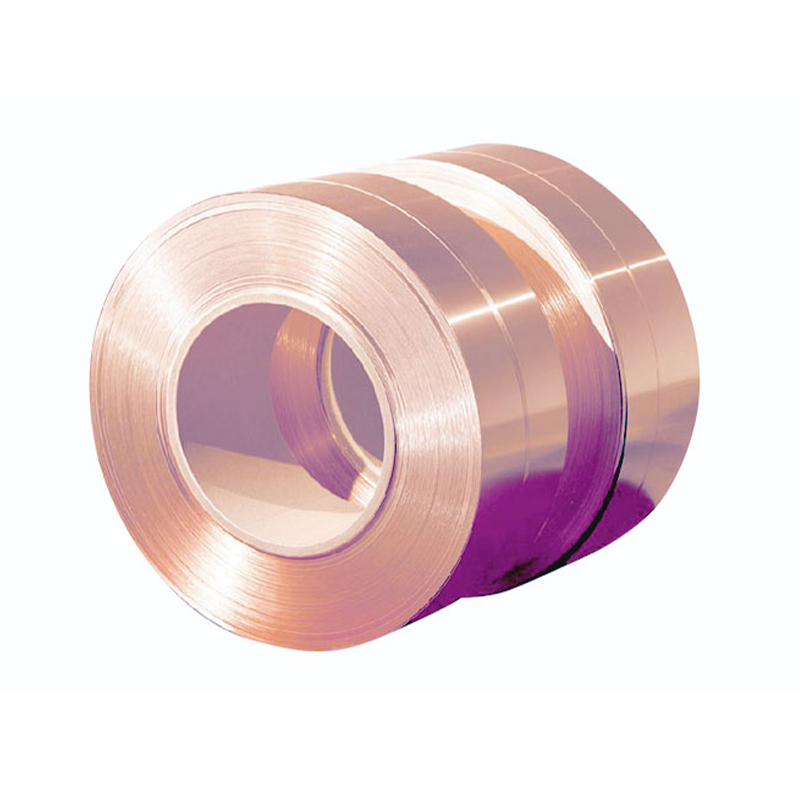

4. Surface silver/nickel plating: prevent oxidation and extend service life

Although copper has excellent electrical and thermal conductivity, it is prone to oxidation in humid or high-temperature environments, affecting electrical conductivity and fusing performance. In order to solve this problem, copper belt safety caps are usually surface-plated with silver or nickel during the manufacturing process. Silver has excellent conductivity and oxidation resistance, while nickel has good corrosion resistance and mechanical strength. This double protection treatment not only improves the conductivity of the copper belt safety cap, but also significantly extends its service life, allowing it to work stably in various harsh environments.

5. Flame retardant and heat insulation performance: double protection circuit safety

The copper belt safety cap not only has good conductivity and fuse response capabilities, but also has excellent flame retardant and heat insulation properties. When the circuit is overloaded or short-circuited, the copper belt safety cap can effectively isolate heat while powering off to prevent high temperature from damaging surrounding components. The material itself will not burn or release harmful gases, which meets the dual requirements of modern electrical equipment for environmental protection and safety. This dual protection mechanism of flame retardancy and heat insulation makes the copper belt safety cap widely used in high-risk places such as power cabinets, industrial control boxes, and data center power distribution systems.

6. Resistance to high and low temperature shock: Stable performance in complex environments

The copper belt safety cap can work stably in an extremely wide temperature range, suitable for a variety of application scenarios from extremely cold outdoor environments to high-temperature industrial sites. Its material and structural design enable it to maintain good conductivity and mechanical strength at extreme temperatures. For example, in a low temperature environment, the conductivity of copper will not decrease significantly; and in a high temperature environment, the copper belt safety cap will not deform or fail due to thermal expansion. This ability to resist high and low temperature shocks makes it have extremely high application value in aerospace, rail transportation, new energy and other fields.

7. Widely used in circuit breakers and fuse systems

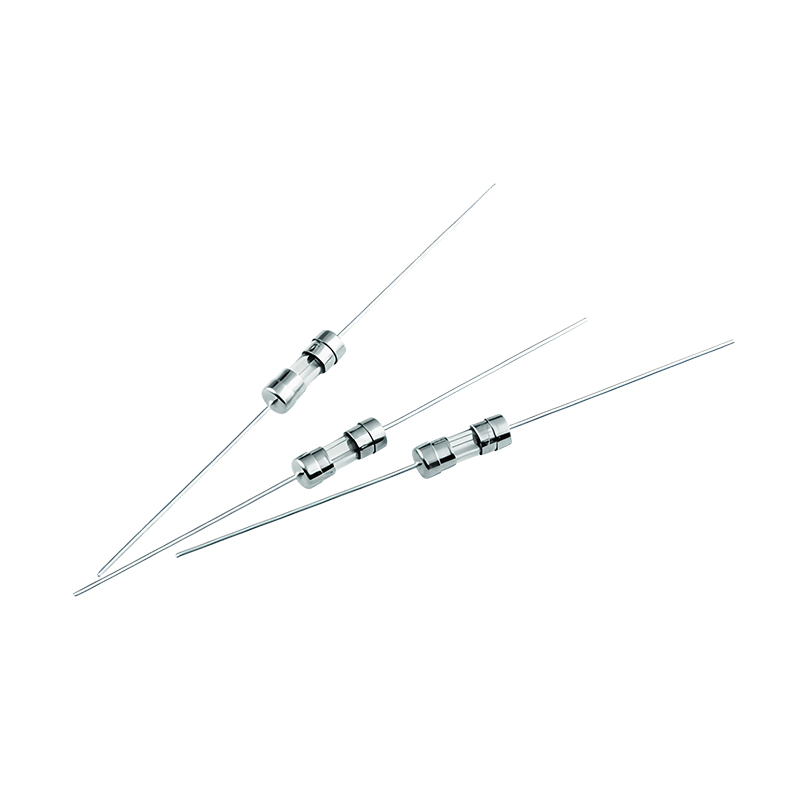

Due to its excellent electrical performance and safety characteristics, copper belt safety cap is widely used in circuit protection devices such as circuit breakers and fuses. In circuit breakers, it can be used as a key fuse component to achieve rapid circuit disconnection; in fuses, it can provide a precise fuse threshold to ensure accurate action at the set current. In addition, copper belt safety cap can also be used in combination with intelligent circuit breaker systems to achieve remote monitoring and automatic protection functions, further improving the intelligent level of circuit management.

8. Environmental protection and sustainable development options

With the global emphasis on environmental protection and sustainable development, copper belt safety cap, as a recyclable and low-pollution circuit protection material, is gradually becoming a new trend in industry development. As a renewable resource, copper has a high recycling rate, low processing energy consumption, and does not release toxic and harmful substances during use, which meets the requirements of green manufacturing and environmental protection regulations. Therefore, the copper belt safety cap not only ensures circuit safety, but also reflects the environmental responsibility of modern industry.

In summary, the copper belt safety cap has shown excellent performance in circuit overload protection with its multiple advantages such as fast response, non-spatter fusing, excellent thermal conductivity, high and low temperature impact resistance, flame retardant and heat insulation. It not only improves the safety and stability of the circuit system, but also has good environmental performance and broad application prospects.

As a key component in modern circuit protection devices, the copper belt safety cap is made of high-quality electrolytic copper strip. Copper has excellent thermal conductivity and can quickly conduct the heat generated by the current to avoid abnormal temperature rise caused by local overheating. At the same time, copper has a moderate melting point (about 1083℃), and when the circuit is overloaded or short-circuited, it can quickly reach the melting temperature and achieve rapid power failure. This feature enables the copper belt safety cap to respond to the fault current within milliseconds, thereby effectively cutting off the power supply and preventing equipment damage or fire accidents.

2. Precision stamping process: weld-free structure improves stability and safety

The copper belt safety cap adopts precision stamping technology, and the entire structure has no welding points, avoiding problems such as cold welding, oxidation or weak structure that may exist in traditional welding processes. This integrated structure is more compact and stable, which not only enhances mechanical strength, but also improves electrical conductivity and thermal conduction efficiency. In the case of a sudden increase in current or high temperature, the copper belt safety cap can maintain structural integrity, ensure that the fusing process is controllable and splash-free, thereby improving the safety of the overall circuit protection.

3. Splash-free fusing: a key feature for achieving safe power off

In traditional fuses or circuit breakers, when the current is overloaded, the fusing process is often accompanied by metal splashing, which may cause secondary short circuits or arc discharges, posing safety hazards. The copper belt safety cap has fully considered this issue in its design. Its unique material properties and structural design prevent metal splashing when it is fusing. Copper maintains a relatively stable form during the melting process and does not form jet-like molten particles, thereby avoiding damage to surrounding electronic components or operators, and achieving a true "safe power off".

4. Surface silver/nickel plating: prevent oxidation and extend service life

Although copper has excellent electrical and thermal conductivity, it is prone to oxidation in humid or high-temperature environments, affecting electrical conductivity and fusing performance. In order to solve this problem, copper belt safety caps are usually surface-plated with silver or nickel during the manufacturing process. Silver has excellent conductivity and oxidation resistance, while nickel has good corrosion resistance and mechanical strength. This double protection treatment not only improves the conductivity of the copper belt safety cap, but also significantly extends its service life, allowing it to work stably in various harsh environments.

5. Flame retardant and heat insulation performance: double protection circuit safety

The copper belt safety cap not only has good conductivity and fuse response capabilities, but also has excellent flame retardant and heat insulation properties. When the circuit is overloaded or short-circuited, the copper belt safety cap can effectively isolate heat while powering off to prevent high temperature from damaging surrounding components. The material itself will not burn or release harmful gases, which meets the dual requirements of modern electrical equipment for environmental protection and safety. This dual protection mechanism of flame retardancy and heat insulation makes the copper belt safety cap widely used in high-risk places such as power cabinets, industrial control boxes, and data center power distribution systems.

6. Resistance to high and low temperature shock: Stable performance in complex environments

The copper belt safety cap can work stably in an extremely wide temperature range, suitable for a variety of application scenarios from extremely cold outdoor environments to high-temperature industrial sites. Its material and structural design enable it to maintain good conductivity and mechanical strength at extreme temperatures. For example, in a low temperature environment, the conductivity of copper will not decrease significantly; and in a high temperature environment, the copper belt safety cap will not deform or fail due to thermal expansion. This ability to resist high and low temperature shocks makes it have extremely high application value in aerospace, rail transportation, new energy and other fields.

7. Widely used in circuit breakers and fuse systems

Due to its excellent electrical performance and safety characteristics, copper belt safety cap is widely used in circuit protection devices such as circuit breakers and fuses. In circuit breakers, it can be used as a key fuse component to achieve rapid circuit disconnection; in fuses, it can provide a precise fuse threshold to ensure accurate action at the set current. In addition, copper belt safety cap can also be used in combination with intelligent circuit breaker systems to achieve remote monitoring and automatic protection functions, further improving the intelligent level of circuit management.

8. Environmental protection and sustainable development options

With the global emphasis on environmental protection and sustainable development, copper belt safety cap, as a recyclable and low-pollution circuit protection material, is gradually becoming a new trend in industry development. As a renewable resource, copper has a high recycling rate, low processing energy consumption, and does not release toxic and harmful substances during use, which meets the requirements of green manufacturing and environmental protection regulations. Therefore, the copper belt safety cap not only ensures circuit safety, but also reflects the environmental responsibility of modern industry.

In summary, the copper belt safety cap has shown excellent performance in circuit overload protection with its multiple advantages such as fast response, non-spatter fusing, excellent thermal conductivity, high and low temperature impact resistance, flame retardant and heat insulation. It not only improves the safety and stability of the circuit system, but also has good environmental performance and broad application prospects.