What are the unique applications of high precision brass strip in the manufacture of fuse copper caps and battery electrode copper caps?

Release Time : 2025-07-01

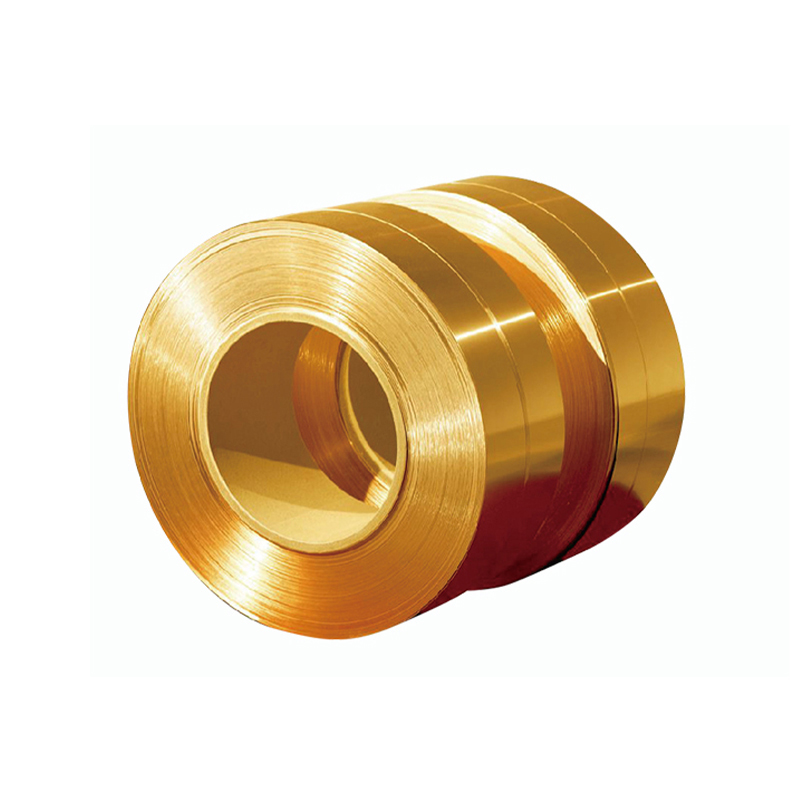

The application of high precision brass strip in the manufacture of fuse copper caps and battery electrode copper caps demonstrates its excellent material properties and wide application potential. First of all, from the perspective of material properties, high precision brass strip has excellent conductivity, good machinability and excellent corrosion resistance, which makes it an ideal choice for manufacturing electronic components.

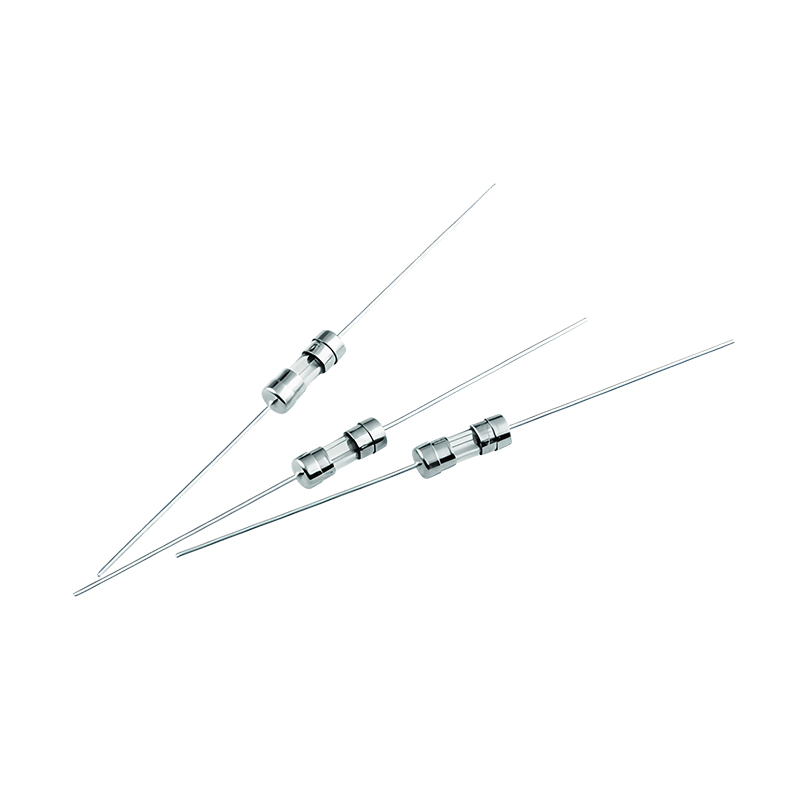

In the production process of fuse copper caps, the conductivity of brass strip is crucial. As an important component of circuit protection, the fuse must be able to respond quickly and accurately to overcurrent conditions to ensure the safe operation of the entire circuit. The copper cap made of brass strip not only provides a stable electrical connection, but also ensures that it will not heat up due to excessive resistance under extreme conditions, thereby affecting the normal operation of the fuse. In addition, the good machinability of brass strip means that it can be accurately stamped into fuse copper caps of various specifications to meet the needs of different types of fuses. This precision is crucial to ensure that each copper cap can perfectly match the corresponding fuse, which not only improves the assembly efficiency of the product, but also enhances the reliability of the final product.

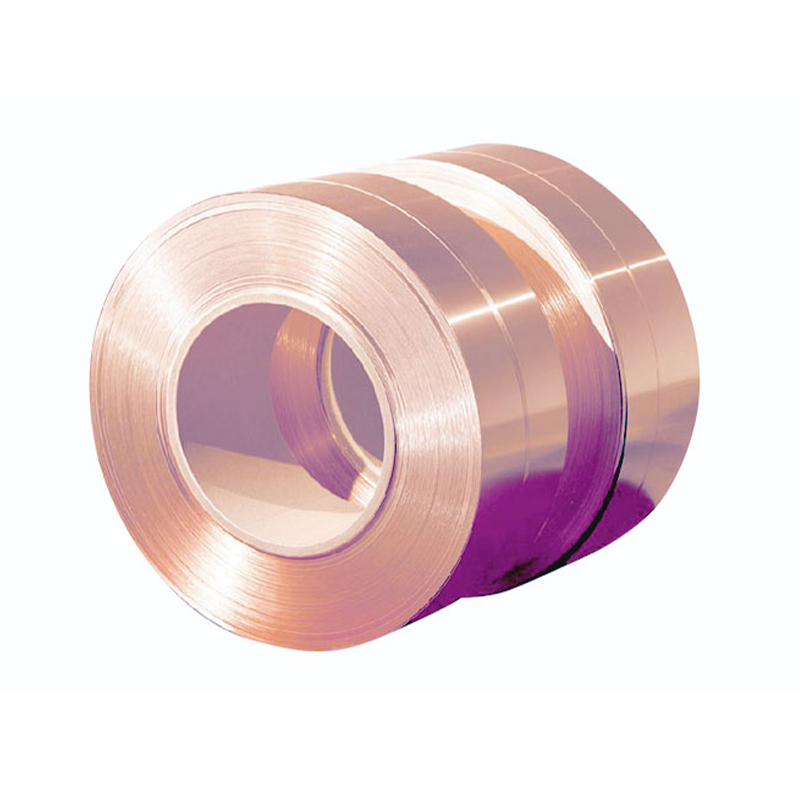

For the copper caps of battery electrodes, the application of high precision brass strip is also indispensable. The internal environment of the battery is complex and changeable, which puts forward strict requirements on the electrode materials. On the one hand, the brass strip needs to have excellent conductivity to facilitate the effective transmission of current; on the other hand, since there may be corrosive substances such as acids and alkalis inside the battery, the material is required to have a certain corrosion resistance. Brass strip just meets these two requirements, and its surface can be further treated by plating to enhance the corrosion resistance and ensure the long-term stable operation of the battery. At the same time, the easy molding characteristics of brass strip also allow it to flexibly adjust the shape and size according to different battery design requirements, and adapt to a wide range of application scenarios from small consumer electronics to large industrial energy storage systems.

In addition to the above basic characteristics, high precision brass strip also performs well in the manufacturing process due to its good ductility and toughness. This enables it to withstand complex processing such as deep drawing, bending and cutting without sacrificing strength. Especially when making thin-walled parts, the advantages of brass strip are more obvious. For example, in some high-end electronic devices, in order to reduce volume and weight, very thin but durable copper caps are often required. At this time, high precision brass strip, with its excellent physical properties, can easily meet these challenges and produce components that are both lightweight and reliable.

Furthermore, considering the trend of environmental protection and sustainable development, brass, as a recyclable metal material, has relatively little impact on the environment throughout its life cycle. This not only conforms to the concept of modern manufacturing in pursuit of green production, but also provides users with a more cost-effective solution. When the product reaches the end of its service life, the brass parts can be recycled and reused to re-enter the production process, reducing resource waste while also reducing the cost of raw material procurement.

In short, the unique application of high precision brass strip in the manufacture of fuse copper caps and battery electrode copper caps fully demonstrates its multiple advantages in electrical performance, mechanical processing performance and environmental protection. Whether it is to ensure circuit safety or support the development of new energy technologies, brass strips play an indispensable role. With the advancement of science and technology and changes in market demand, it is believed that brass strips will show more possibilities for innovative applications in the future and continue to drive the development of related industries.

In the production process of fuse copper caps, the conductivity of brass strip is crucial. As an important component of circuit protection, the fuse must be able to respond quickly and accurately to overcurrent conditions to ensure the safe operation of the entire circuit. The copper cap made of brass strip not only provides a stable electrical connection, but also ensures that it will not heat up due to excessive resistance under extreme conditions, thereby affecting the normal operation of the fuse. In addition, the good machinability of brass strip means that it can be accurately stamped into fuse copper caps of various specifications to meet the needs of different types of fuses. This precision is crucial to ensure that each copper cap can perfectly match the corresponding fuse, which not only improves the assembly efficiency of the product, but also enhances the reliability of the final product.

For the copper caps of battery electrodes, the application of high precision brass strip is also indispensable. The internal environment of the battery is complex and changeable, which puts forward strict requirements on the electrode materials. On the one hand, the brass strip needs to have excellent conductivity to facilitate the effective transmission of current; on the other hand, since there may be corrosive substances such as acids and alkalis inside the battery, the material is required to have a certain corrosion resistance. Brass strip just meets these two requirements, and its surface can be further treated by plating to enhance the corrosion resistance and ensure the long-term stable operation of the battery. At the same time, the easy molding characteristics of brass strip also allow it to flexibly adjust the shape and size according to different battery design requirements, and adapt to a wide range of application scenarios from small consumer electronics to large industrial energy storage systems.

In addition to the above basic characteristics, high precision brass strip also performs well in the manufacturing process due to its good ductility and toughness. This enables it to withstand complex processing such as deep drawing, bending and cutting without sacrificing strength. Especially when making thin-walled parts, the advantages of brass strip are more obvious. For example, in some high-end electronic devices, in order to reduce volume and weight, very thin but durable copper caps are often required. At this time, high precision brass strip, with its excellent physical properties, can easily meet these challenges and produce components that are both lightweight and reliable.

Furthermore, considering the trend of environmental protection and sustainable development, brass, as a recyclable metal material, has relatively little impact on the environment throughout its life cycle. This not only conforms to the concept of modern manufacturing in pursuit of green production, but also provides users with a more cost-effective solution. When the product reaches the end of its service life, the brass parts can be recycled and reused to re-enter the production process, reducing resource waste while also reducing the cost of raw material procurement.

In short, the unique application of high precision brass strip in the manufacture of fuse copper caps and battery electrode copper caps fully demonstrates its multiple advantages in electrical performance, mechanical processing performance and environmental protection. Whether it is to ensure circuit safety or support the development of new energy technologies, brass strips play an indispensable role. With the advancement of science and technology and changes in market demand, it is believed that brass strips will show more possibilities for innovative applications in the future and continue to drive the development of related industries.