How does the copper tape connector ensure the stability of the electrical connection?

Release Time : 2025-06-17

Copper tape connector plays a key role in the field of electrical connection. Its ability to ensure the stability of electrical connection is related to the reliable operation of the entire circuit system. From the perspective of material selection, copper itself has excellent conductivity and is an ideal carrier for current transmission. Copper tape connector is made of high-purity copper material. Its internal atoms are arranged regularly, and electrons can move smoothly in it, reducing resistance and reducing the risk of unstable connection caused by heat generated by excessive resistance.

In terms of structural design, copper tape connector has been carefully considered. The common crimping copper tape connector uses a specific mold and process to tightly press the copper tape and the connection terminal together. This crimping is not a simple physical extrusion, but a close molecular bond between the copper tape and the terminal, which greatly increases the contact area. The increase in contact area means that the current flow path is wider and the current distribution is more uniform, thereby avoiding problems such as overheating and oxidation of the connection point caused by excessive local current, and effectively ensuring the stability of the electrical connection.

Surface treatment process is also an important link to ensure the stability of electrical connection. Copper is easily oxidized in the air, and the generated oxide layer will increase the contact resistance and affect current transmission. To solve this problem, copper tape connectors are usually treated with tin plating, silver plating, etc. The tin plating layer can not only effectively isolate the copper from the air and prevent oxidation, but also improve the solderability of the connector to a certain extent, making the welding more secure; while the silver plating layer, with its higher conductivity, further reduces the contact resistance, ensuring that the current can pass stably and efficiently at the connection point.

Mechanical fastening methods are also indispensable for the stability of electrical connections. Many copper tape connectors use bolt fastening or snap-on connections to firmly fix the components together. When the bolts are tightened, the torque can be precisely controlled to ensure that there is enough pressure between the connected components to maintain close contact without damaging the copper tape or other components due to excessive pressure. The snap-on connection achieves fast and reliable connection with its ingenious structural design, and can still maintain a stable connection when subjected to slight vibration or external force, avoiding unstable electrical connection due to looseness.

The copper tape connector is also equipped with special insulation protection measures. In a complex electrical environment, electromagnetic interference may occur between different lines, affecting the normal transmission of current. The insulating shell of the connector can effectively isolate external interference, prevent stray current from entering, and ensure that the current flows along the predetermined path. At the same time, insulation protection can also avoid safety hazards caused by leakage, and ensure the stability of electrical connections from both safety and functionality.

In addition, the copper tape connector will fully consider the thermal expansion factor when designing. When current passes through, the connector will generate a certain amount of heat, causing the copper tape and other components to expand due to heat. Reasonable structural design can allow the copper tape to expand and contract freely within a certain range, avoiding the deformation or loosening of the connection components due to stress caused by thermal expansion and contraction, thereby ensuring that the electrical connection can remain stable under different temperature environments.

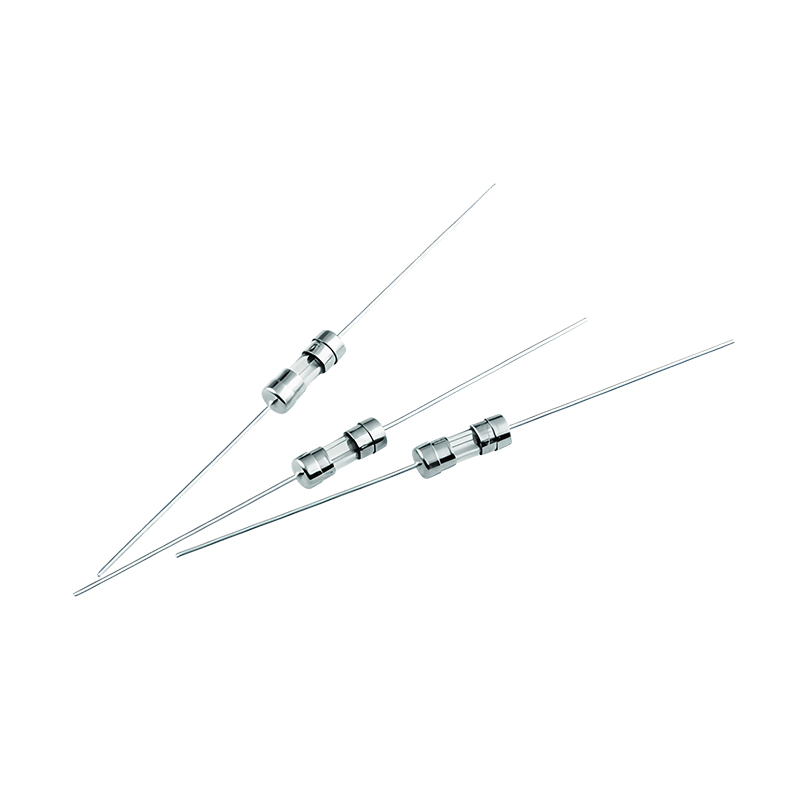

In actual applications, copper tape connectors will also undergo rigorous testing and screening. Manufacturers will simulate various complex usage scenarios and conduct electrical performance tests, mechanical performance tests, and environmental adaptability tests on connectors. Only connectors that have passed these rigorous tests will be put on the market, ensuring that each copper tape connector has good electrical connection stability from the source.