Why has high precision copper strip become an indispensable core material in the electronics and power industries?

Release Time : 2025-06-02

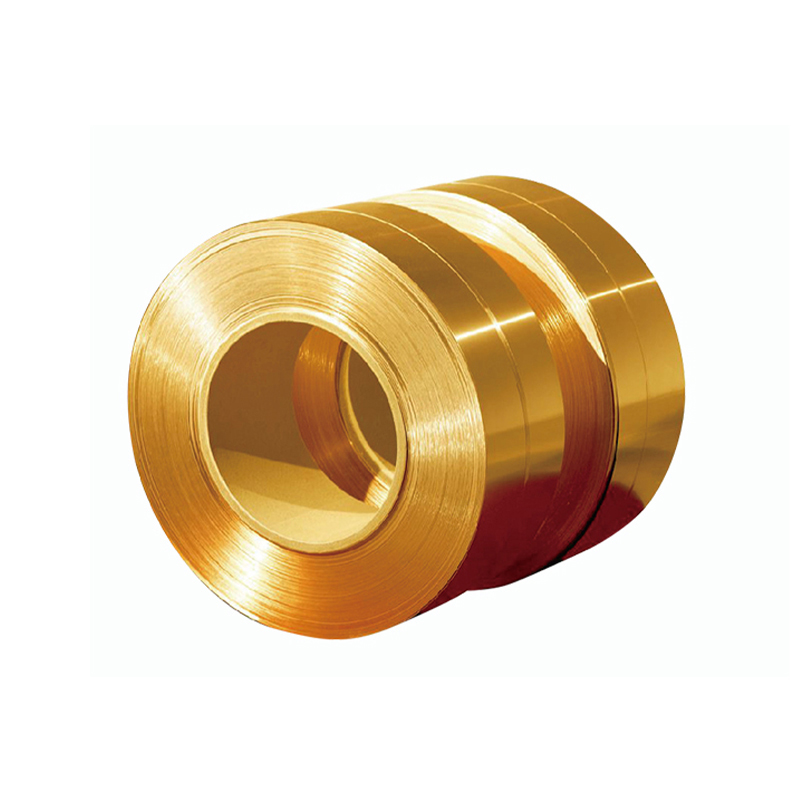

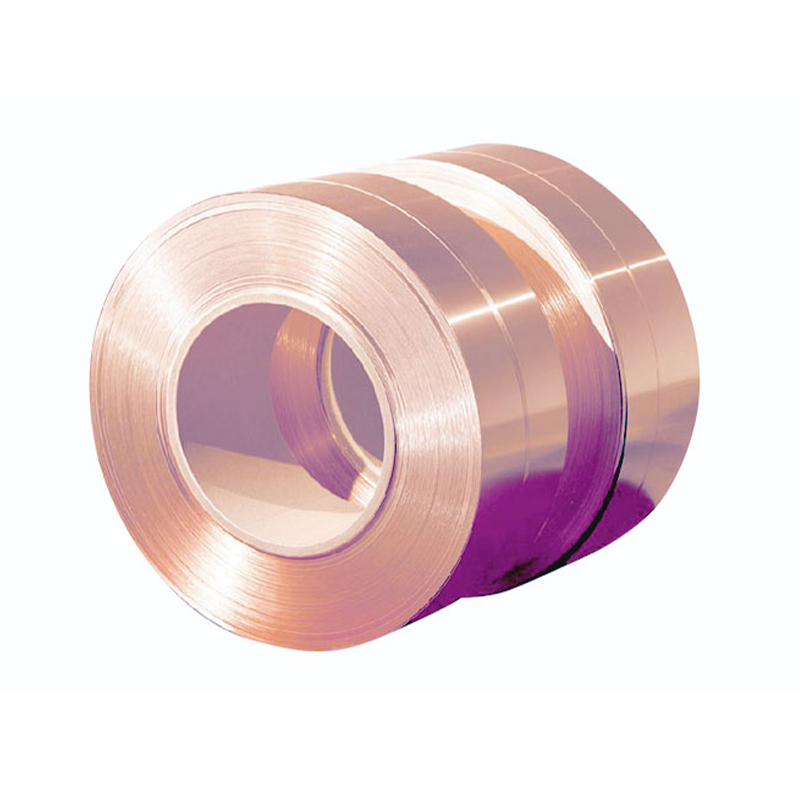

In the modern industrial system, especially in the fields of power, electronics, communications and new energy, the demand for metal materials with excellent electrical and thermal conductivity is growing. As a key basic material, high precision copper strip is widely used in various high-tech products and equipment with its excellent electrical conductivity, thermal conductivity, corrosion resistance and good processing and welding performance, and has become an important support for promoting industrial upgrading and technological progress.

The most significant advantage of high precision copper strip is its excellent electrical and thermal conductivity. Copper itself has excellent electron mobility, which makes the material perform well in transmitting current and dissipating heat. This makes it the preferred material for manufacturing high-demand electronic components, transformers, transistors, coaxial cables, waveguides and other products. Especially in scenarios such as high-frequency communications, 5G base station construction, and data center server heat dissipation, high precision copper strip can effectively ensure stable signal transmission and efficient system operation, avoiding performance degradation or equipment damage caused by heat accumulation.

In addition, this type of copper strip has excellent corrosion resistance and can be used stably for a long time in a humid, high temperature or even slightly chemically corrosive environment. This characteristic makes it not only suitable for traditional power equipment such as bus ducts and conductive strips, but also widely used in fire-fighting equipment, high-voltage switchgear, photovoltaic solar panels and new energy batteries, which have extremely high safety requirements. For example, in new energy vehicle power batteries, high precision copper strips are often used as connecting pieces to ensure the high efficiency of current conduction and the reliability of the structure.

In terms of processing adaptability, high precision copper strips also perform outstandingly. It is not only easy to stamp, bend, and stretch, but also has good weldability and brazing properties, and can achieve a firm connection with a variety of metal materials to meet the needs of complex assembly processes. This makes it easier to achieve high-precision, large-scale manufacturing on automated production lines, improving overall production efficiency and finished product consistency.

With the development of green energy and intelligent manufacturing, the application scope of high precision copper strips is constantly expanding. From smart grids to energy storage systems, from 5G communication equipment to electric vehicle electronic control modules, to new composite tapes and high-frequency electronic components, it plays an irreplaceable role. Especially in the context of the rapid rise of the new energy industry, copper strips, as key materials for internal connections in battery modules and conductive paths in charging systems, continue to grow in market demand and become an important force in promoting the transformation of clean energy.

It is worth mentioning that high-quality high precision copper strip adopts advanced melting, cold rolling and surface treatment technology in the manufacturing process to ensure its small thickness tolerance, high surface finish and uniform mechanical properties, which fully meets the requirements of high-end electronic and power equipment for material precision and miniaturization. At the same time, this type of copper strip can also be customized according to customer needs, such as different widths, thicknesses, hardness grades and surface coating treatments to adapt to various application scenarios.

In summary, high precision copper strip has shown strong product advantages in many industries such as electricity, electronics, communications, and new energy with its excellent electrical and thermal conductivity, stable corrosion resistance, good processing adaptability and broad application prospects. So, are you also looking for an ideal metal material that can ensure electrical conductivity and meet complex processing requirements? High precision copper strip is undoubtedly your ideal choice.

The most significant advantage of high precision copper strip is its excellent electrical and thermal conductivity. Copper itself has excellent electron mobility, which makes the material perform well in transmitting current and dissipating heat. This makes it the preferred material for manufacturing high-demand electronic components, transformers, transistors, coaxial cables, waveguides and other products. Especially in scenarios such as high-frequency communications, 5G base station construction, and data center server heat dissipation, high precision copper strip can effectively ensure stable signal transmission and efficient system operation, avoiding performance degradation or equipment damage caused by heat accumulation.

In addition, this type of copper strip has excellent corrosion resistance and can be used stably for a long time in a humid, high temperature or even slightly chemically corrosive environment. This characteristic makes it not only suitable for traditional power equipment such as bus ducts and conductive strips, but also widely used in fire-fighting equipment, high-voltage switchgear, photovoltaic solar panels and new energy batteries, which have extremely high safety requirements. For example, in new energy vehicle power batteries, high precision copper strips are often used as connecting pieces to ensure the high efficiency of current conduction and the reliability of the structure.

In terms of processing adaptability, high precision copper strips also perform outstandingly. It is not only easy to stamp, bend, and stretch, but also has good weldability and brazing properties, and can achieve a firm connection with a variety of metal materials to meet the needs of complex assembly processes. This makes it easier to achieve high-precision, large-scale manufacturing on automated production lines, improving overall production efficiency and finished product consistency.

With the development of green energy and intelligent manufacturing, the application scope of high precision copper strips is constantly expanding. From smart grids to energy storage systems, from 5G communication equipment to electric vehicle electronic control modules, to new composite tapes and high-frequency electronic components, it plays an irreplaceable role. Especially in the context of the rapid rise of the new energy industry, copper strips, as key materials for internal connections in battery modules and conductive paths in charging systems, continue to grow in market demand and become an important force in promoting the transformation of clean energy.

It is worth mentioning that high-quality high precision copper strip adopts advanced melting, cold rolling and surface treatment technology in the manufacturing process to ensure its small thickness tolerance, high surface finish and uniform mechanical properties, which fully meets the requirements of high-end electronic and power equipment for material precision and miniaturization. At the same time, this type of copper strip can also be customized according to customer needs, such as different widths, thicknesses, hardness grades and surface coating treatments to adapt to various application scenarios.

In summary, high precision copper strip has shown strong product advantages in many industries such as electricity, electronics, communications, and new energy with its excellent electrical and thermal conductivity, stable corrosion resistance, good processing adaptability and broad application prospects. So, are you also looking for an ideal metal material that can ensure electrical conductivity and meet complex processing requirements? High precision copper strip is undoubtedly your ideal choice.